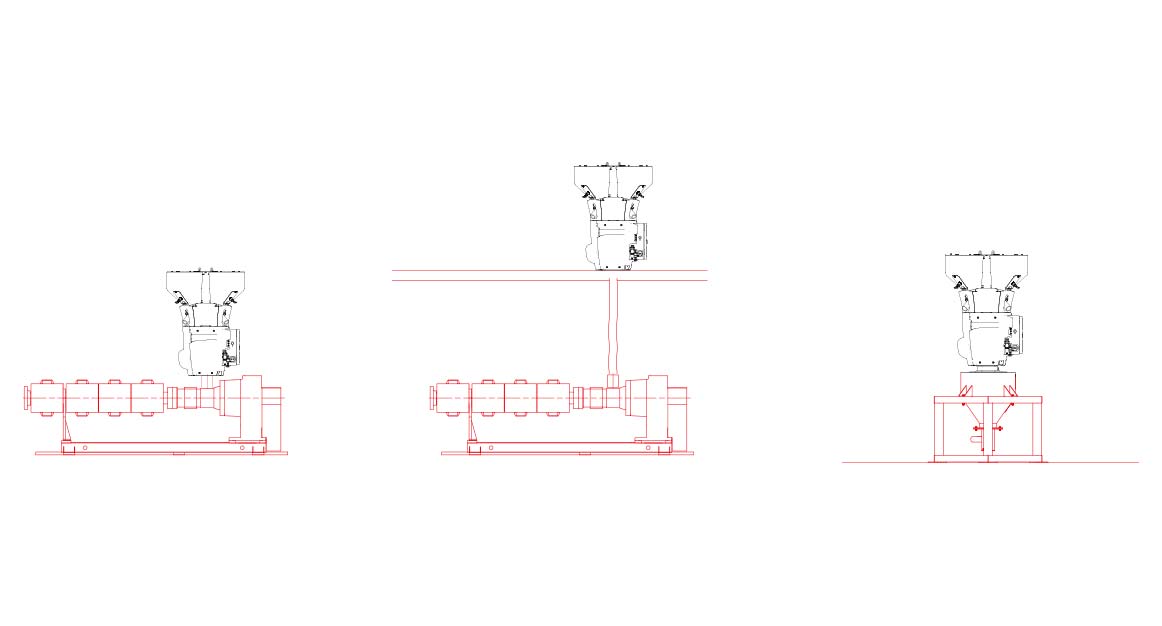

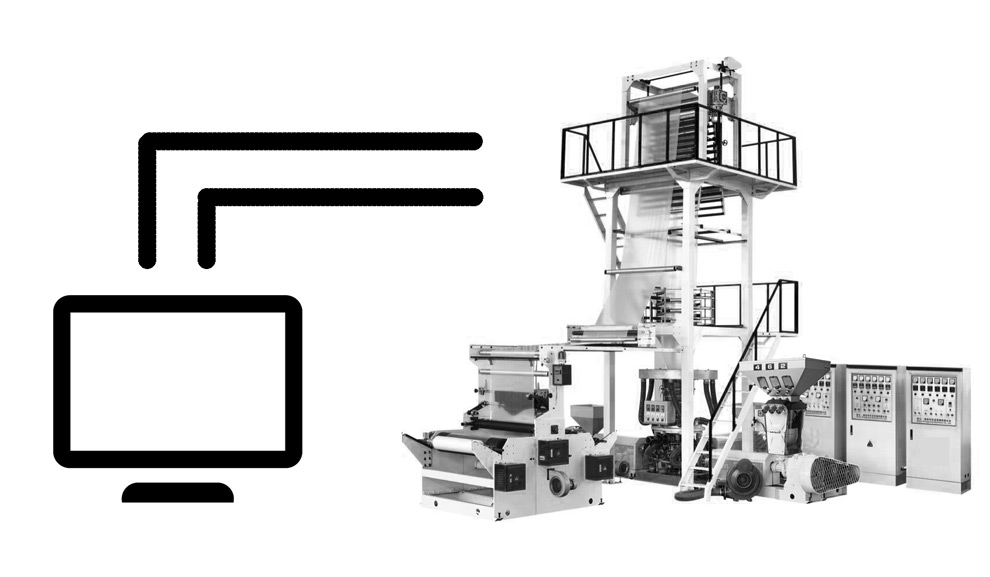

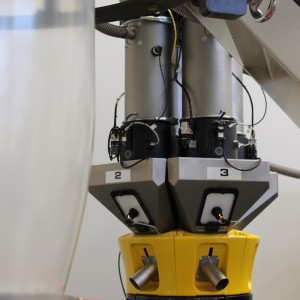

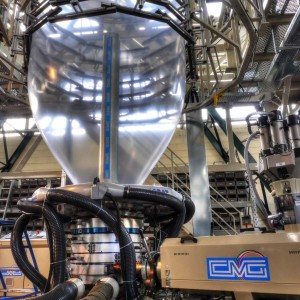

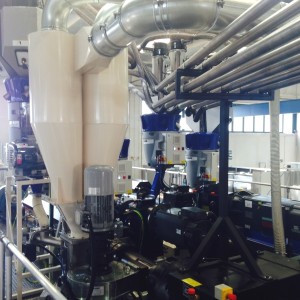

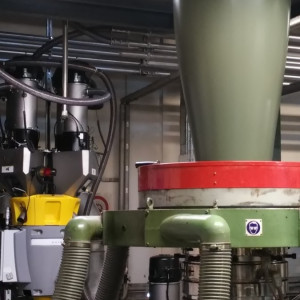

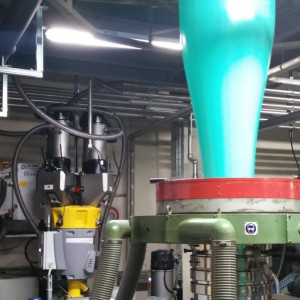

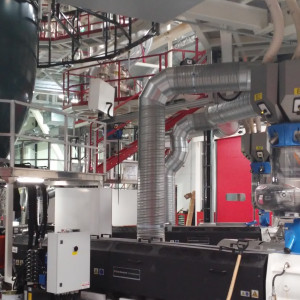

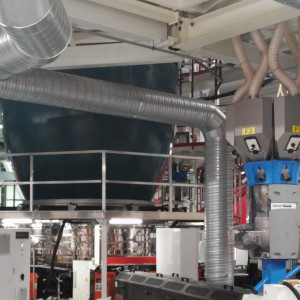

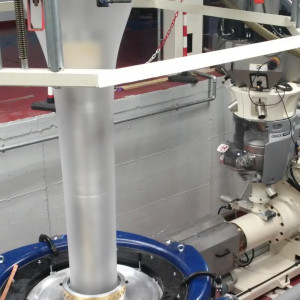

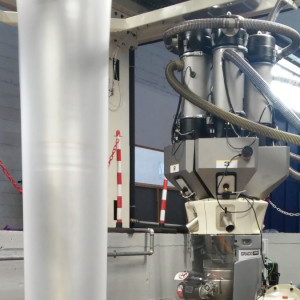

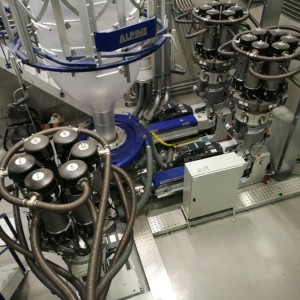

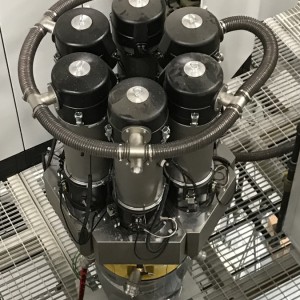

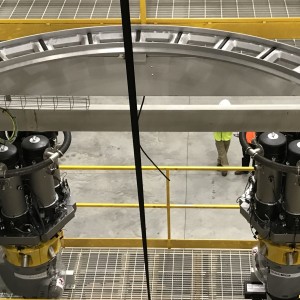

Gravimetric batch blender, designed to blend free flowing pellets in processes which require accurate dosing and repeatability with efficient mixing. Unaffected by vibrations, GRADO ADROIT has been designed to be easily mounted directly onto the throat of the processing machine, to be installed either on a mezzanine, or on a vacuum take-off stand to feed one or more extruders.

Grado Adroit – Gravimetric batch blender and extrusion control

SUPERIOR DESIGN COMPLYING RIGOROUS PROCESS REQUIREMENT

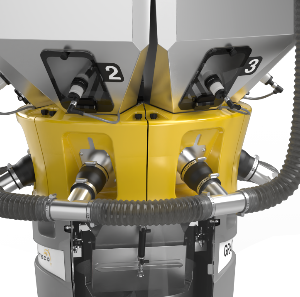

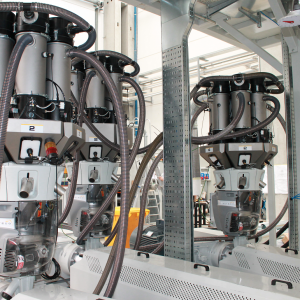

- Full modular construction

- For ingredient change, there is no need to stop and “dismantle” the machine

- Practical and easy access to all parts for maintenance or quick and accurate cleaning

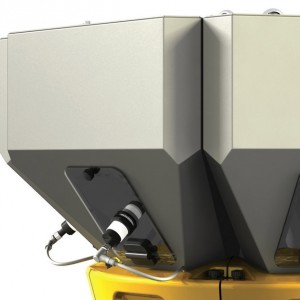

- Drain spout for quick and complete ingredient feed hopper emptying

- Clean out doors for fast removal of dust or ingredient residues and for visual inspection

- Round bottom mixer can be completely emptied leaving no trace of residue material

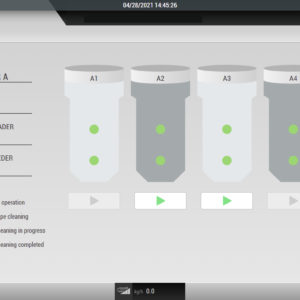

- Easy to use, simply set the dosing percentage

UNSURPASSABLE ENGINEERING AT TOP LEVEL IMPROVES RELIABILITY

- Number of parts reduced at minimum

- No one hand-made part, but cast aluminum, molded custom engineered plastic compounds, machined steel

- PLC based control from market leader producer

- Re-engineered manufacturing process reducing delivery time

IMPROVED THROUGHPUT CAPACITY IN A COMPACT SIZE

- Advanced high noise immunity weighing system reduces weight measurement time

- Throughput capacity results improved as per faster weighing cycle time

SUPERIOR BLENDING ACCURACY AND PRECISION

- Enhanced control dynamics and weight measurement quality improves process capability

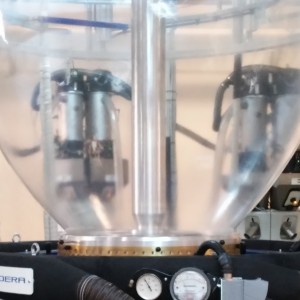

MIXING CHAMBER SIZING IMPROVES BLENDING CONSISTENCY

- The 3 batches mixing chamber capacity ensure the right mixing time and improves blending consistency

- As the motor mixer has a round bottom, there are no stagnation areas. The mixing paddle moves the entire mass of material resulting in a homogeneous blend and preventing the formation of preferential flows that would favor the separation of the ingredients into finer, heavier or more flowing granule sizes.

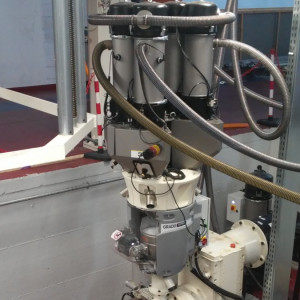

- Full modular construction, from two to six components

- Self-supporting structure prearranged for vacuum receiver installation without additional supports

- All parts that come into contact with the ingredients are made of food-grade materials or finishes

- Removable individual hopper for each ingredient

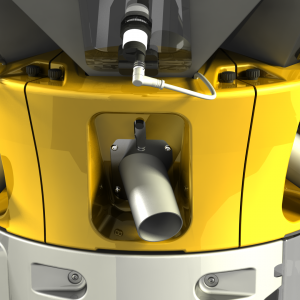

- Patent pending dispense valve, slide gate type

- Round bottom mixing chamber with rotating paddles driven by AC motor, continuous or timed functioning

- Mixer on load cell for a precise extruder throughput measurement and control

- The on-board control box does not require any floor space

- Standard type load cells, high resolution weighing system (16 bit A/D converter) to maximize analog accuracy

- Doteco own developed software

- Flashing alarm signal and diagnostics in plain text

- No scheduled maintenance required

- Reduced installation costs. Complete wiring of the dosing unit is factory made

- Minimum level sensors

- Integrated gravimetric extrusion control (GraviLine) as option

- Integrated loading system control (SmartConvey) as option

- Each ingredient is fed, in sequence, into the weigh bin through slide gate valves.

- On reaching the preset batch weight, a special sensor signal causes the batch to be discharged into the mixing chamber

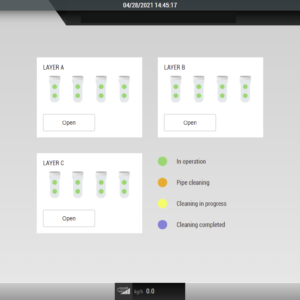

GRAVICLEAN is an automatic cleaning system for GRADO ADROIT blenders.

It automatically performs the cleaning operations to prepare the dosing stations in the event of a material change. Ideal for lines where production changes are frequent, GRAVICLEAN is 100% retrofittable on pre-existing lines.

Integrated loading system control (SmartConvey)

Fully automated loading system control, easy operated by the same interface used for gravimetric blenders. One or more vacuum pumps to serve more than one receivers whose association can be set through configuration. All receivers linked to the same pump are served in turn, according to a priority sequence automatically assigned. Loading active control to reduce ingredient at minimum on changeover

Side component dosing

- Volumetric feeder for additives designed to be mounted on a neck riser, between the processing machine feed hopper and the extruder throat.

Materials suction lances

- Different designs to ensure optimal suctioning regardless of the material bulk density.

WIDE RANGE OF NETWORKING OPTIONS FOR REMOTE CONTROL AND DATA ACQUISITION

- OPC via Ethernet (one entry-point)

- OPC via CanBus (one entry-point or multi entry-point)

- ModBus TCP/IP (one entry-point)

- RS485/422 ModBus (one entry-point or multi entry-point)

- Profibus (one entry-point or multi entry-point)

- CanBus (one entry-point or multi entry-point)

- Profinet (one entry-point)

- Ethernet I/P (one entry point)