24 Sep K 2025 DOTECO PRODUCT SHOWCASE

From 8 to 15 October 2025, K in Düsseldorf will once again be the central stage for the international plastics and rubber industry. And what better opportunity to showcase our latest solutions?

Here is a sneak peek at what visitors will discover in our area at the PiovanGroup stand (Hall 10, C20).

ON DISPLAY

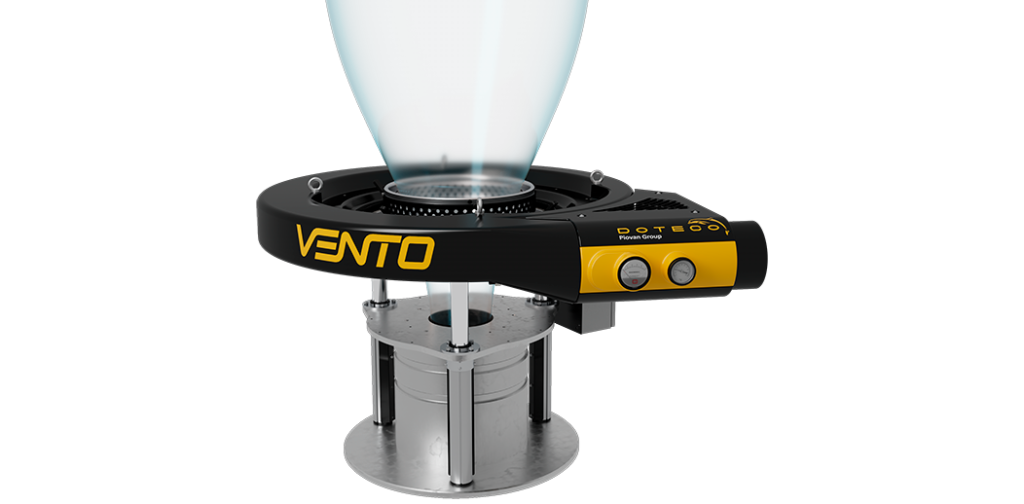

VENTO – NEW OPTIONS TO BOOST PRODUCTIVITY

VENTO is DOTECO’s automatic film cooling and thickness control system. The air ring is specifically designed to minimize friction and pressure drops, ensuring exceptional cooling efficiency and bubble stability. This results in increased output rates and superior film quality,

At K 2025 we are introducing two new accessories developed to further increase line performance and enhance film properties: the lifting device and the double chimney.

AIR-RING LIFTING DEVICE

The effectiveness of the cooling is proportional to the surface where the air gets in contact with the bubble. By elevating the air ring to cool the bubble where its surface is larger, it is possibile to maximize the air-flow cooling effect, boosting the line output rate and enhancing the film technical properties.

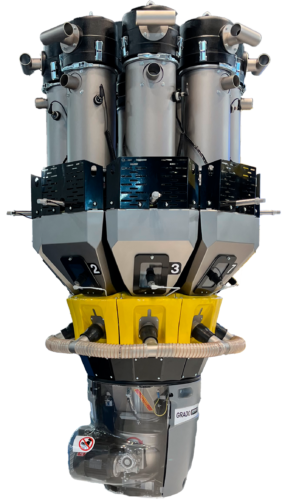

GRADO ADROIT 8 + GRAVICLEAN

On display at K 2025 GRADO ADROIT OTTO, the 8 components version of GRADO ADROIT gravimetric batch blenders line. Its extreme versatility combined with high performance and field-tested reliability makes it the ideal tool for a wide range of applications.

GRADO ADROIT 8 will be equipped with GRAVICLEAN, the automatic cleaning system, that automatically performs the cleaning processes to prepare the dosing stations for recipe changes.

GRAVICLEAN is ideal for lines where production changes are frequent.

ADVANTAGES of GRAVICLEAN

- Time management: All time-consuming activities related to manual cleaning are performed faster and more efficiently.

- Cost reduction: a faster cleaning procedure leads to less material consumed and less scrap generated while it is performed.

- Increase in quality: the careful elimination of any residue minimizes the risk of contamination in subsequent productions.

BLENDO ADROIT

Does the extrusion process require high dosing accuracy and homogeneous dispersion of additives? BLENDO ADROIT continuous loss-in-weight gravimetric blenders are the go-to choice.

-

-

- High accuracy and precision even at low dosing rates

- Excellent additive mixing thanks to the cascade mixer’s special design

- Complete modularity

-

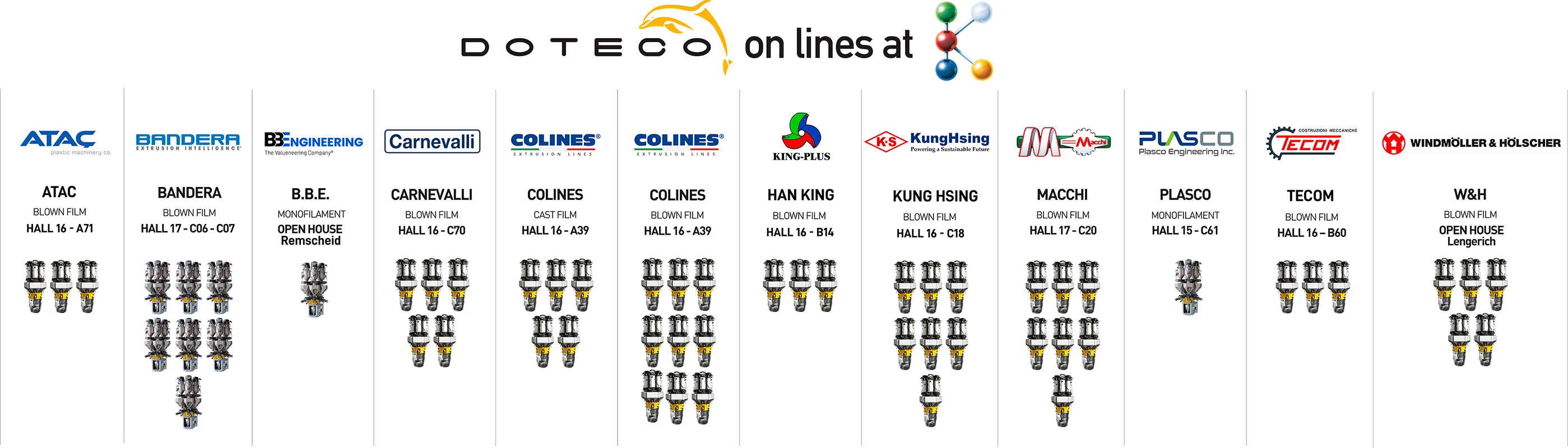

ON LINES

Would you like to see some gravimetric blender in action?

No problem! There will be more than 50 Doteco machines running on our partners’ extrusion lines, both directly at the show and during open-house events.

To know where to find our blenders, please refer to the image below. (click on the image to enlarge).

The contents on the website www.doteco.com of which Doteco S.p.A. is the author they cannot be copied because they belong to the author himself. Copying and reproduction of the contents in any way or form is prohibited. The sharing and redistribution of content is permitted as long as the source is cited and the link to the page from which they were taken is reported. Copyright © 2025 Doteco S.p.A. All rights reserved