The high quality standards and material technical requirements for new applications require a constant improvement in production process and the introduction of increasingly efficient systems for the automation, monitoring and control of processes and quality certification.

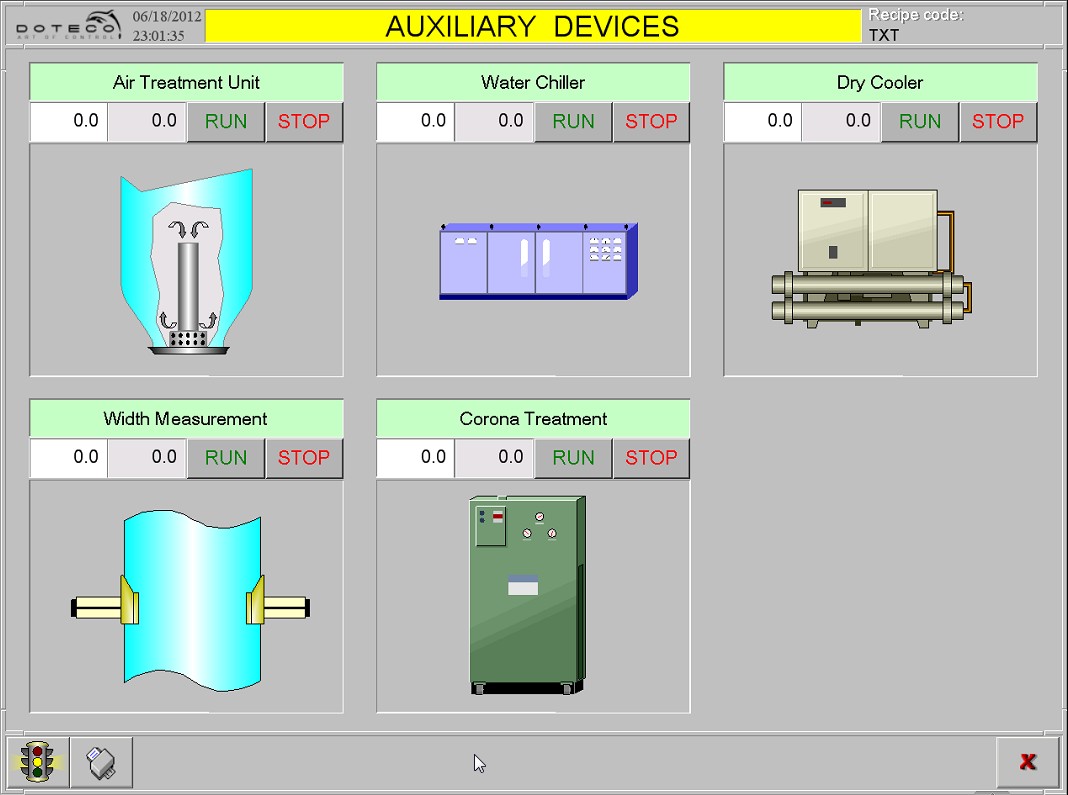

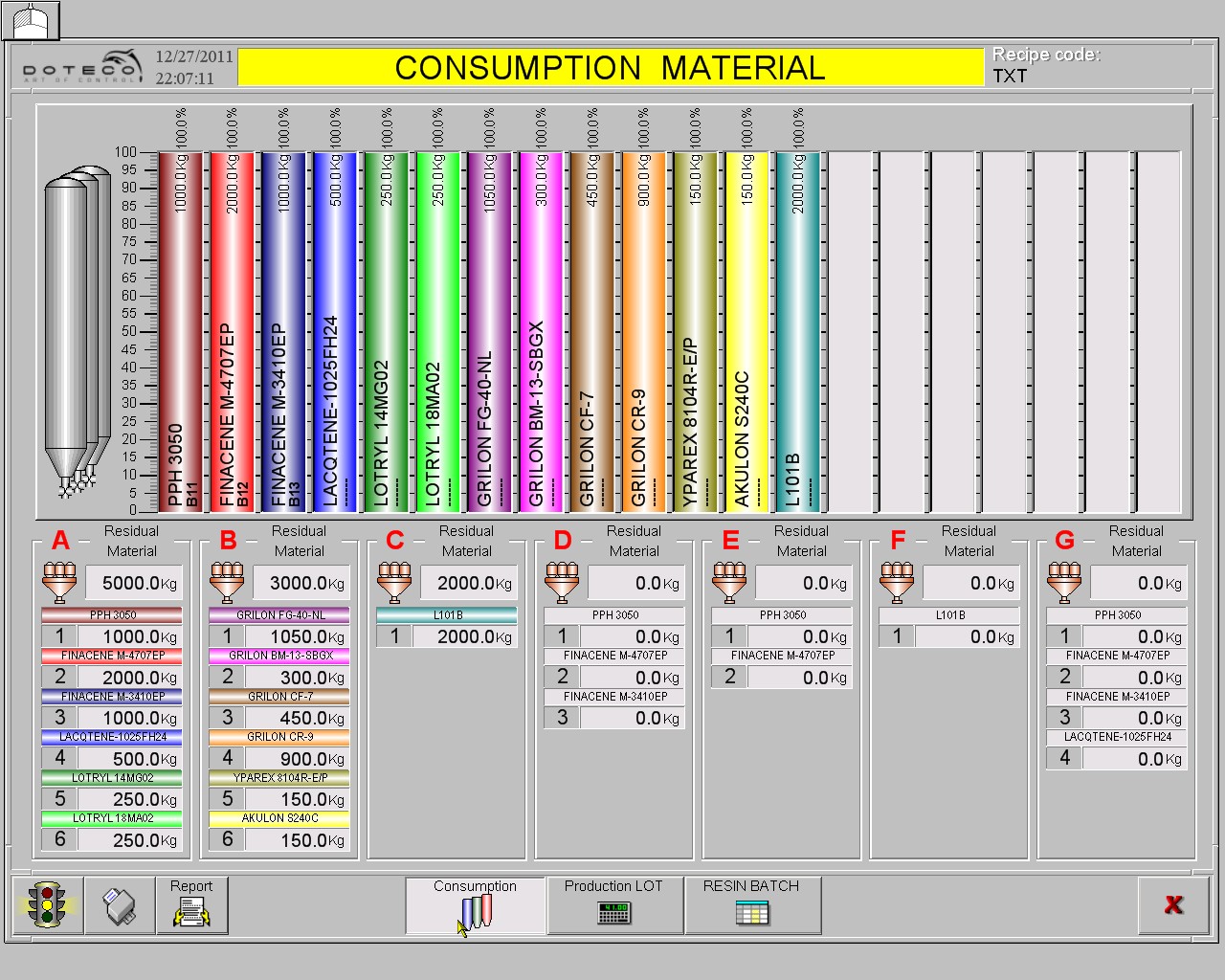

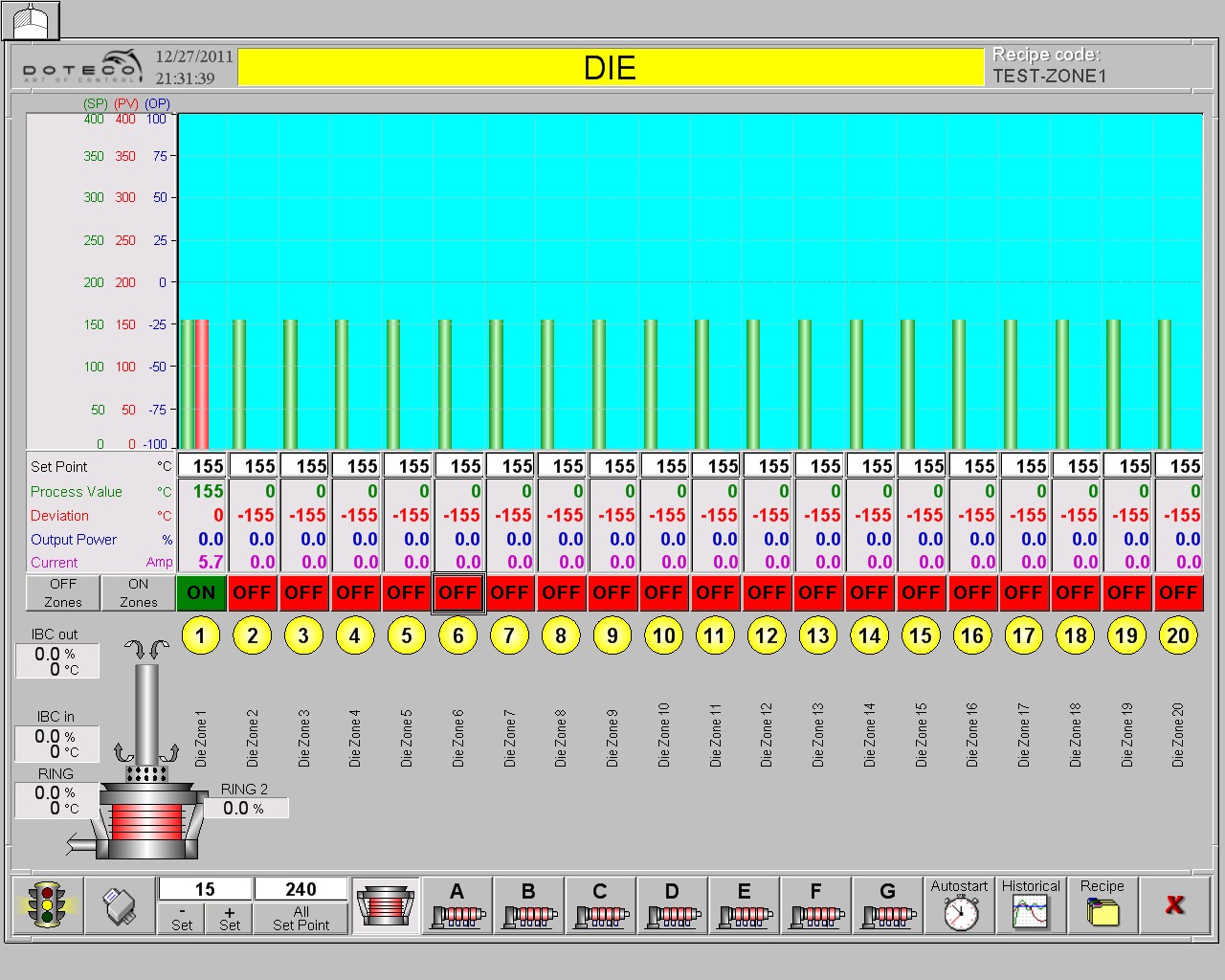

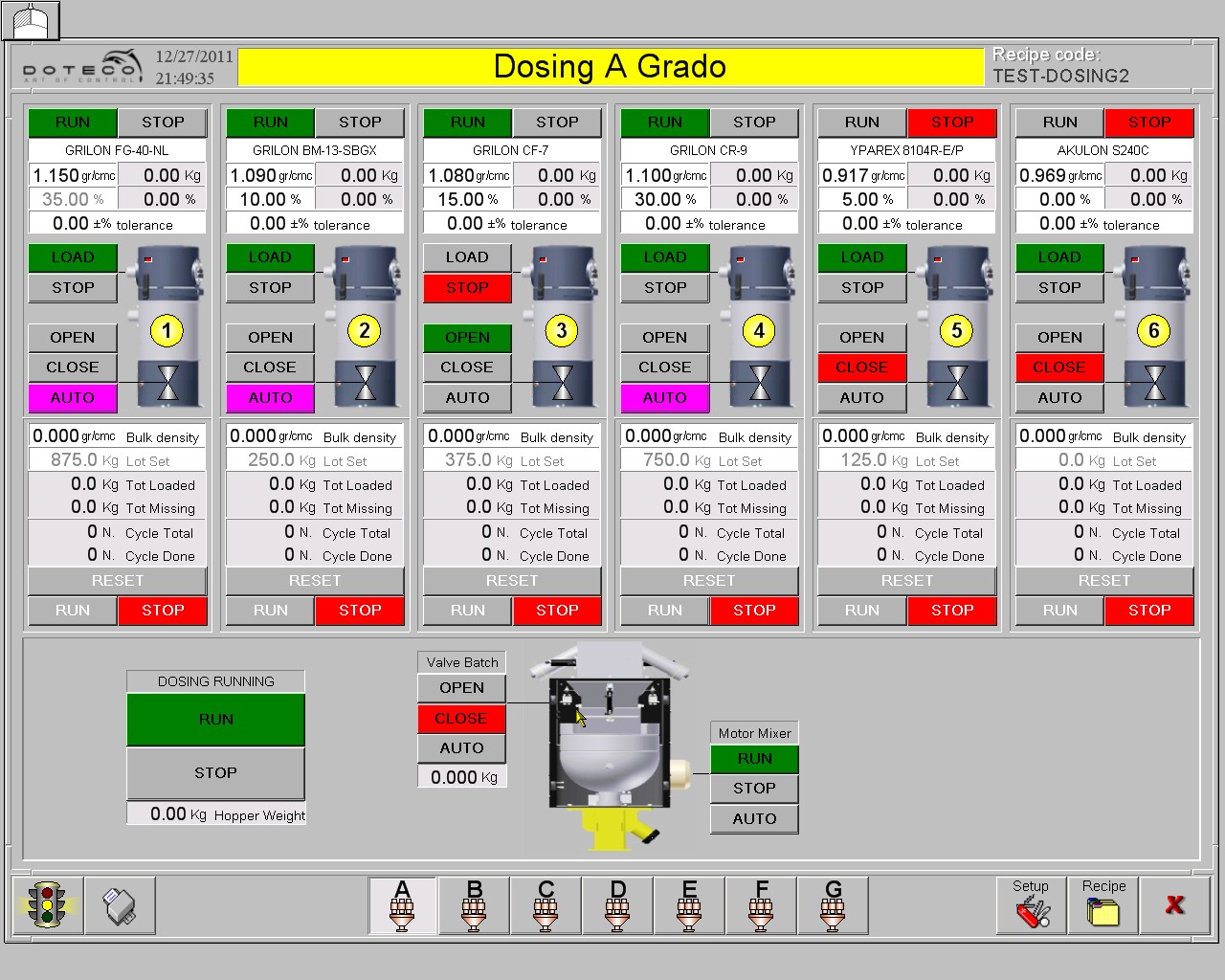

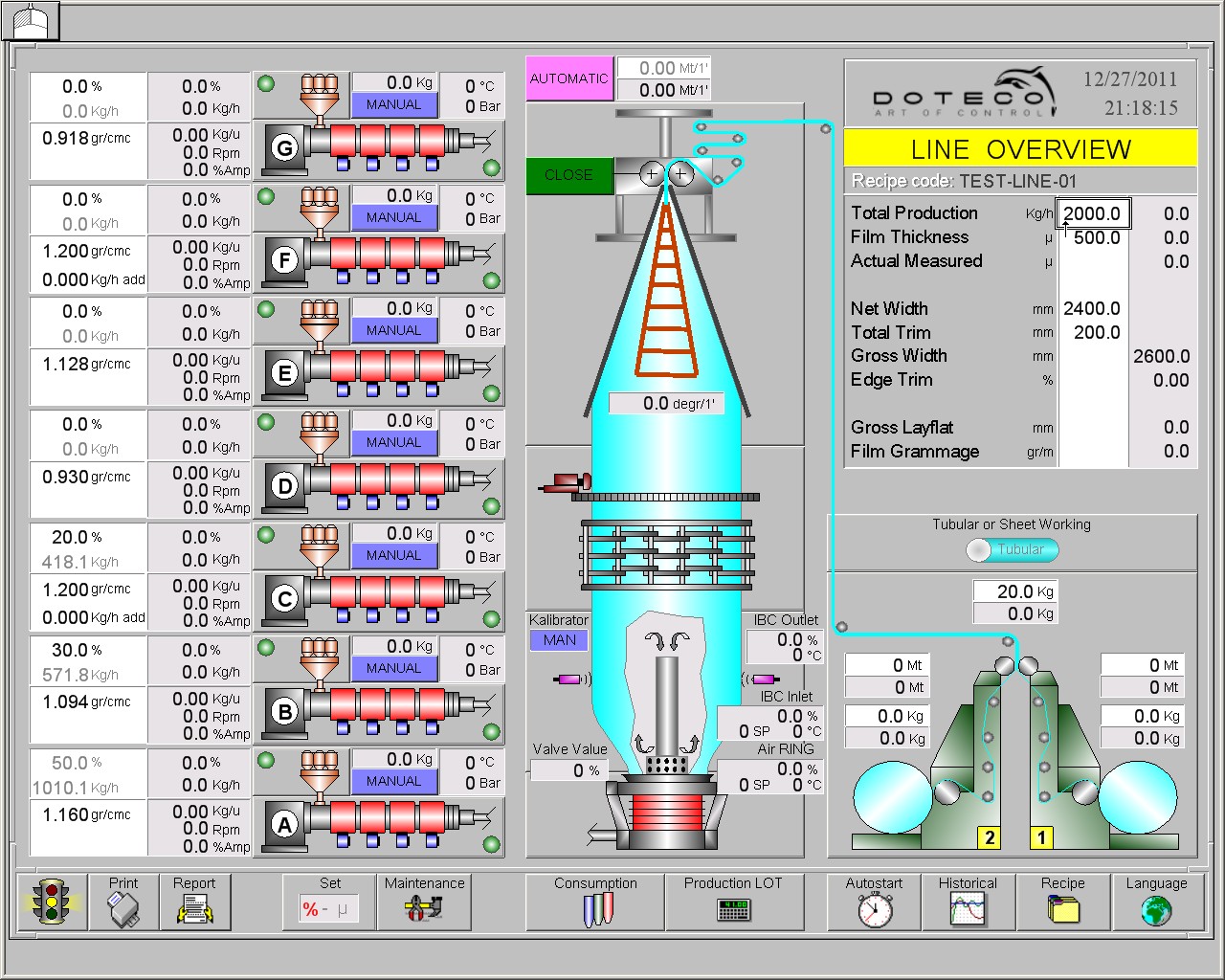

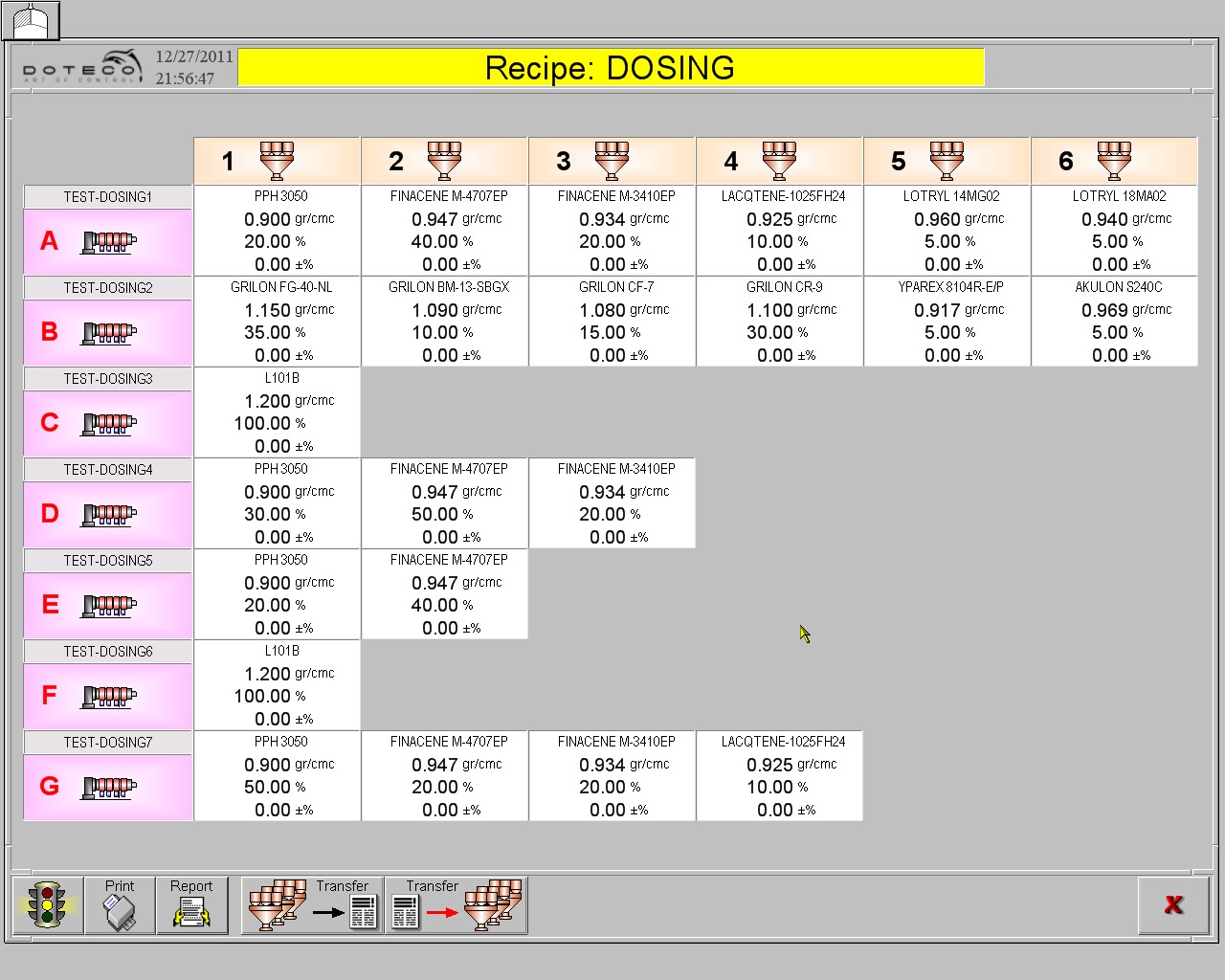

- Simple and easy management of the extrusion system

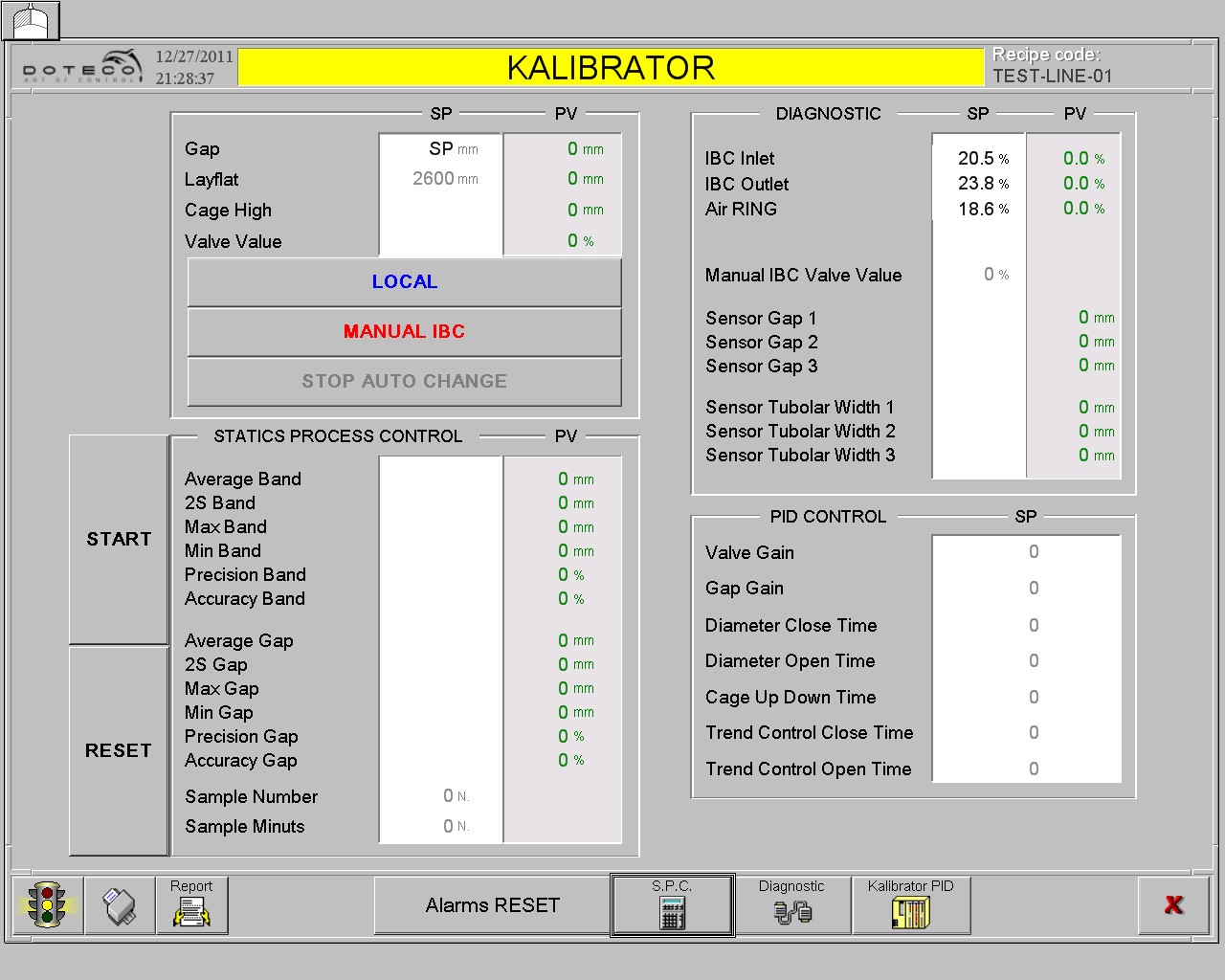

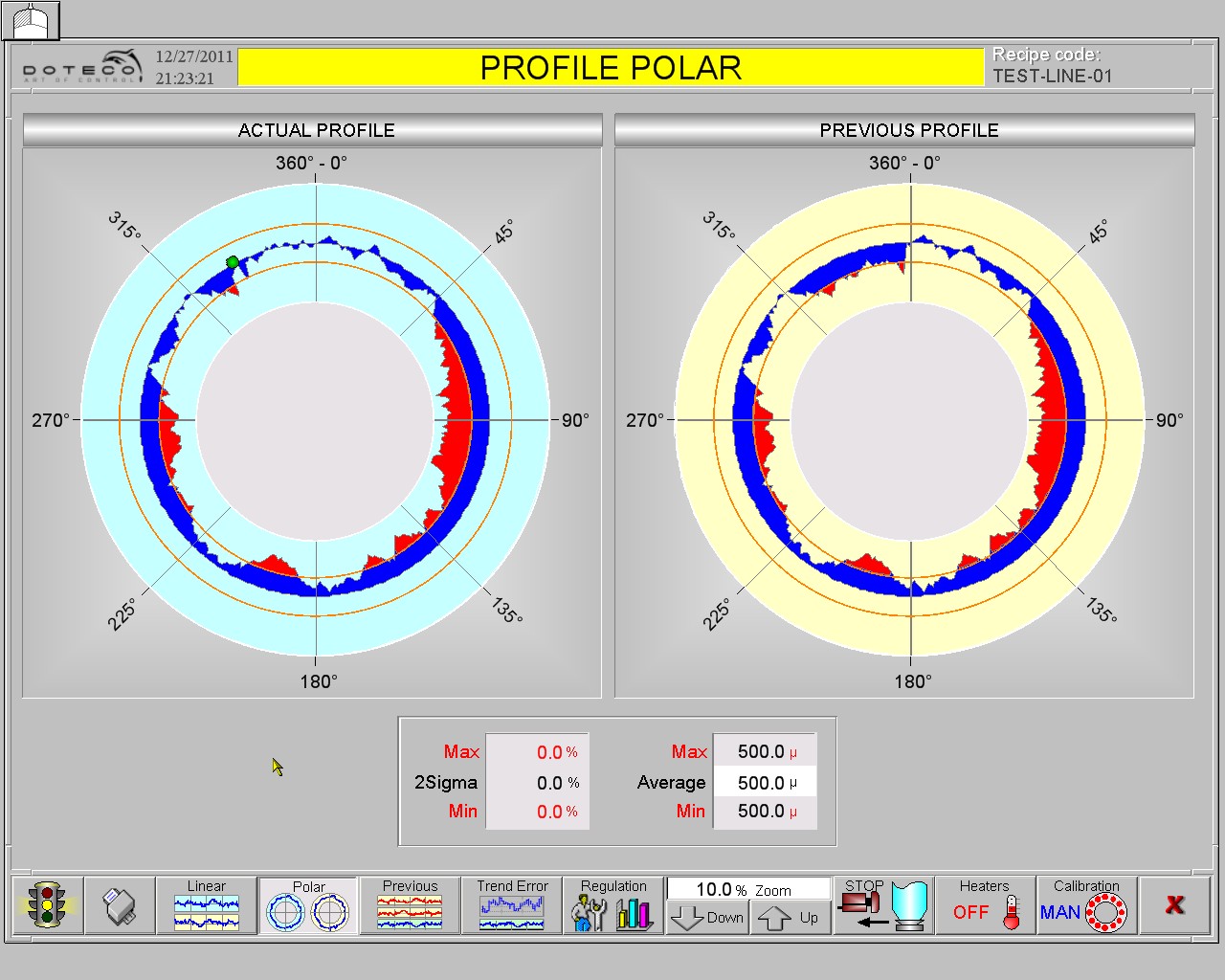

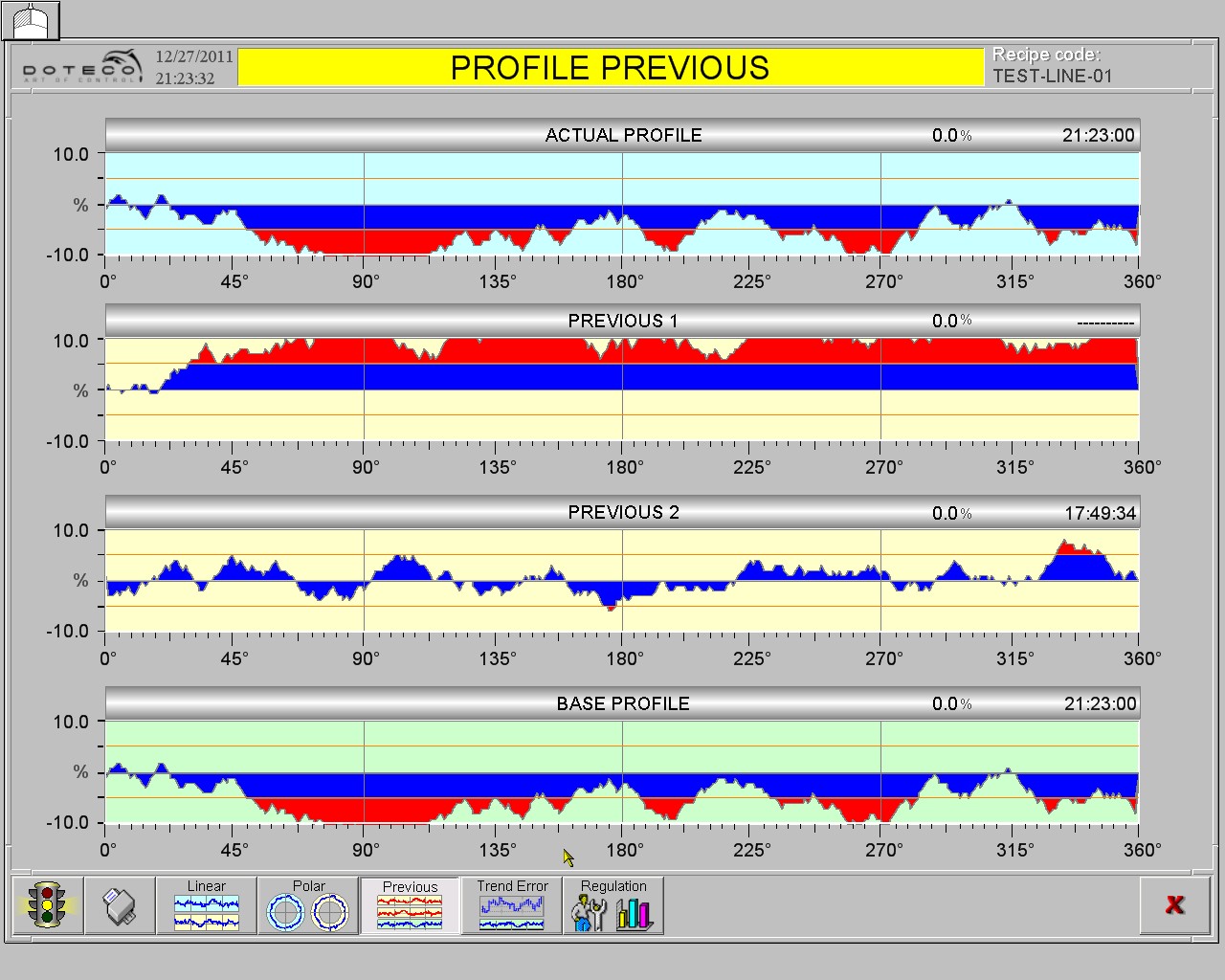

- Complete control of process functions

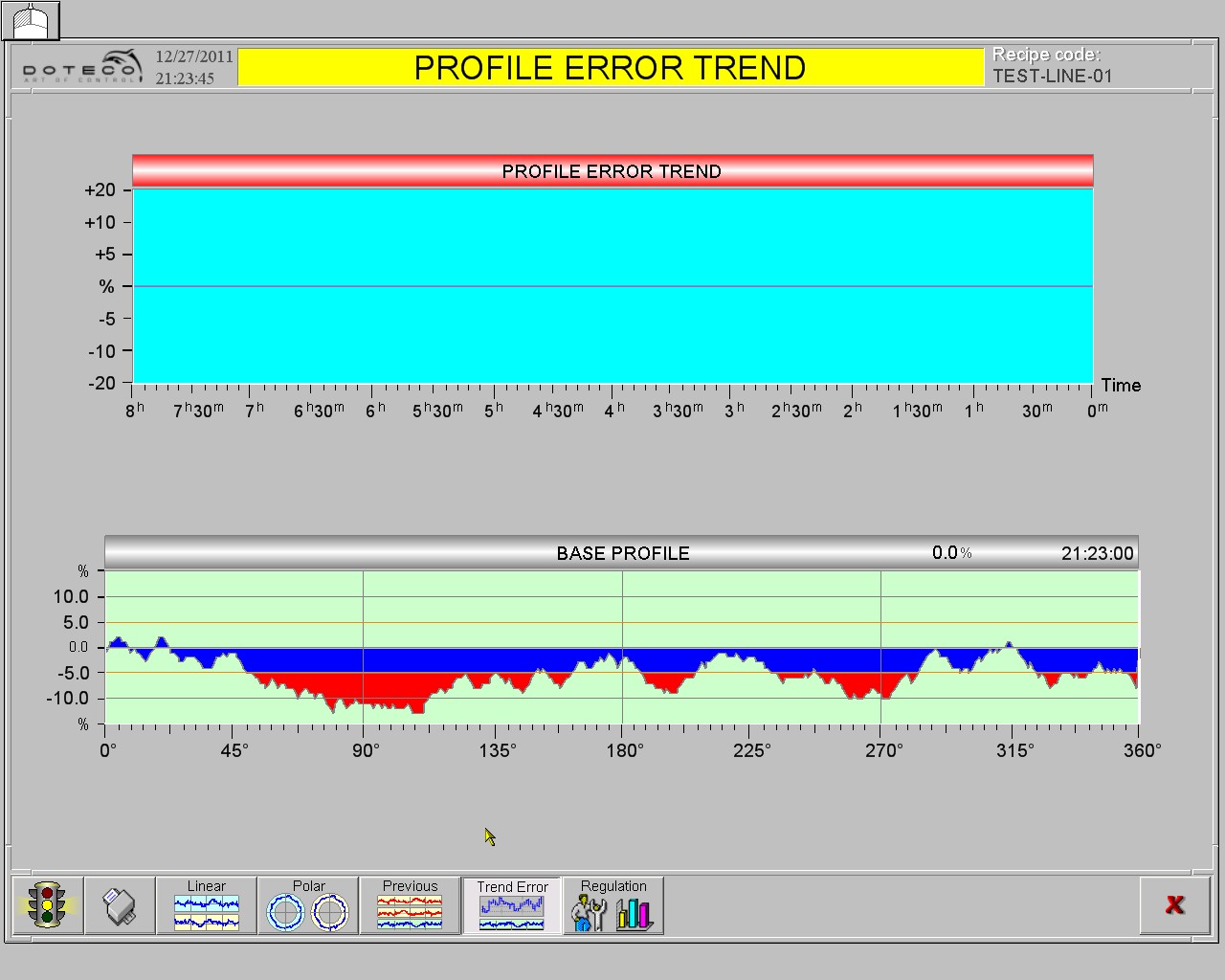

- Monitor the process in real time, with immediate and detailed warning of any faults or malfunction

- Provides a complete monitoring and control of the extrusion process