READY TO BE BLOWN AWAY?

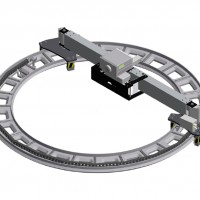

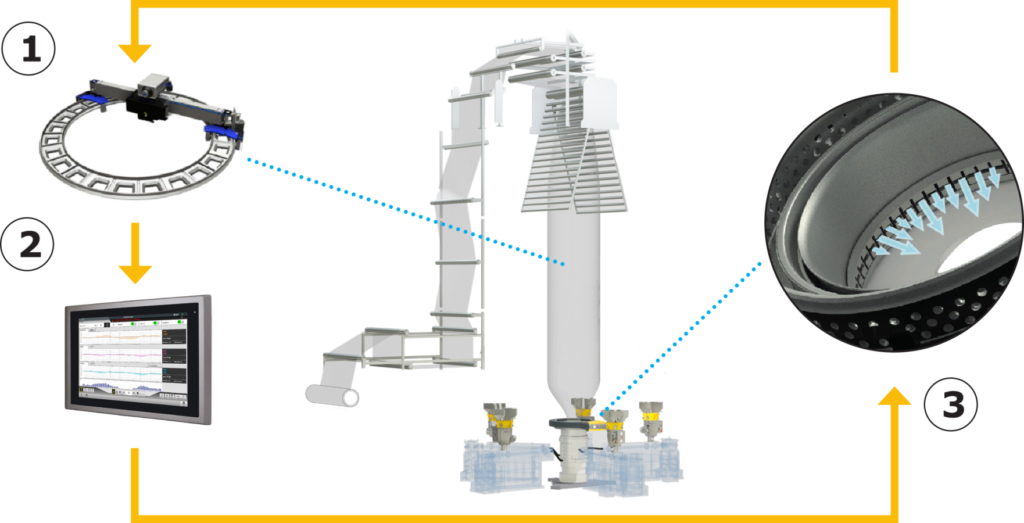

VENTO is the new automatic film cooling and thickness control system by DOTECO.

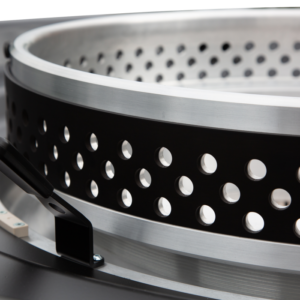

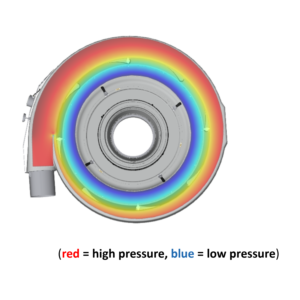

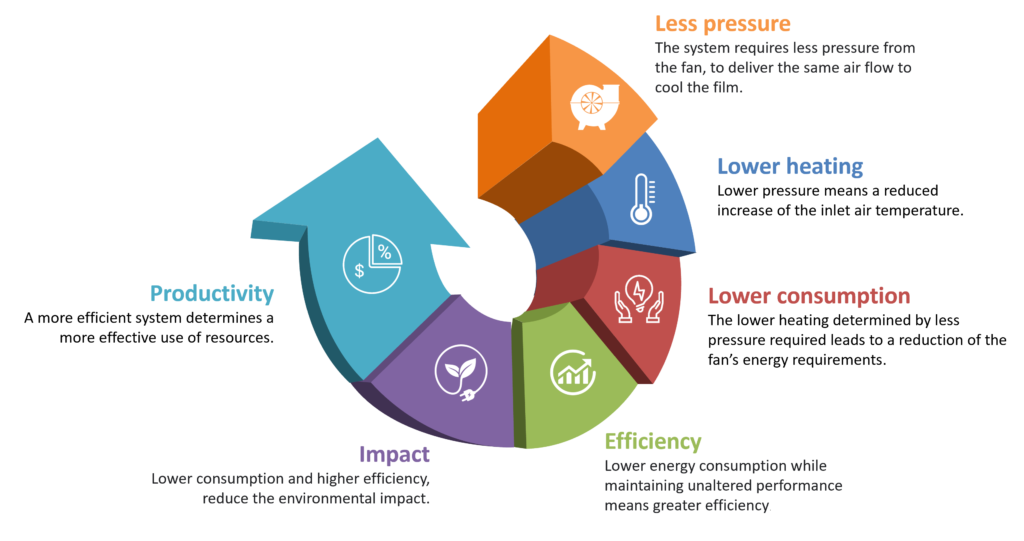

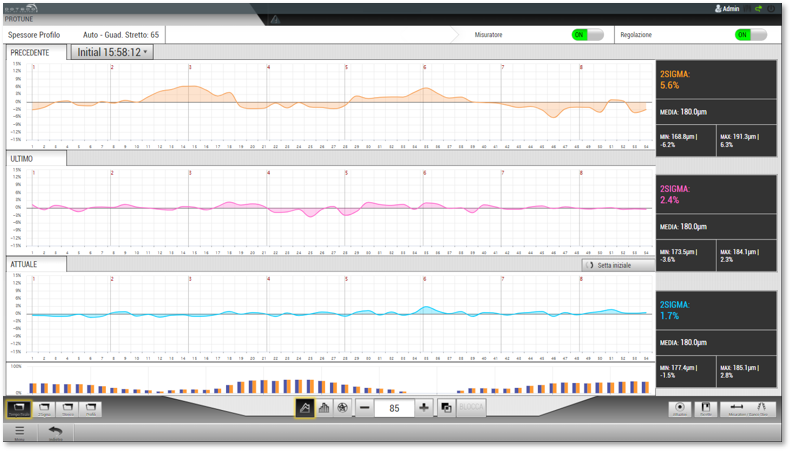

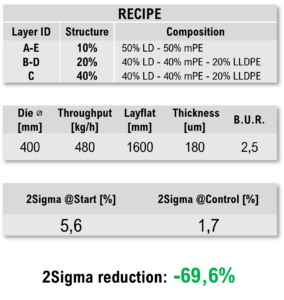

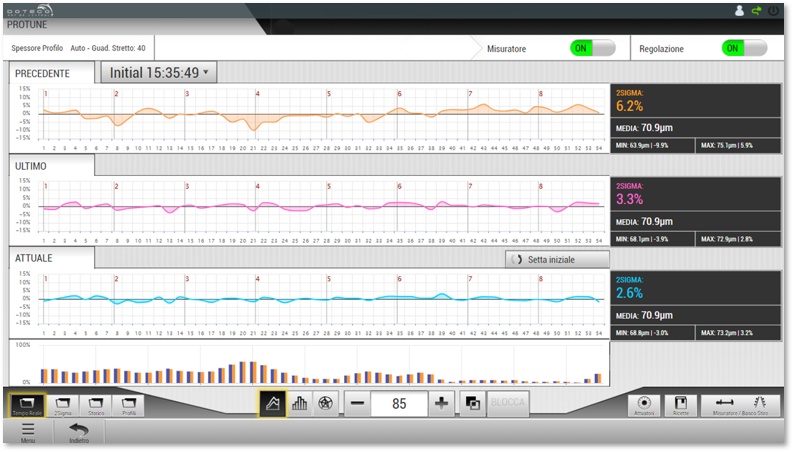

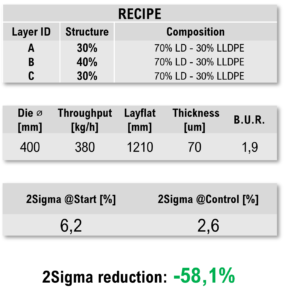

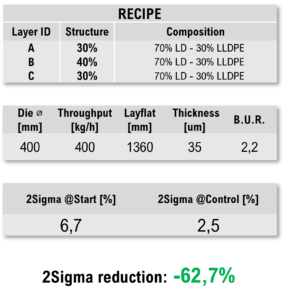

The air ring, specifically designed to minimize friction and pressure drops, allows energy consumption optimization and high performance in terms of 2Sigma reduction and thickness uniformity.

Dedicated air flows ensure maximum cooling efficiency and bubble stability.

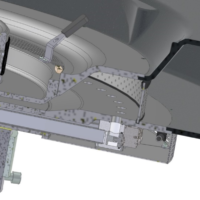

Suitable for low and high stalk bubbles, it can be easily installed on pre-exhisting lines.

VENTO is also available without automatic thickness control (VENTO ST), ideal for processes where only cooling of the film is required.