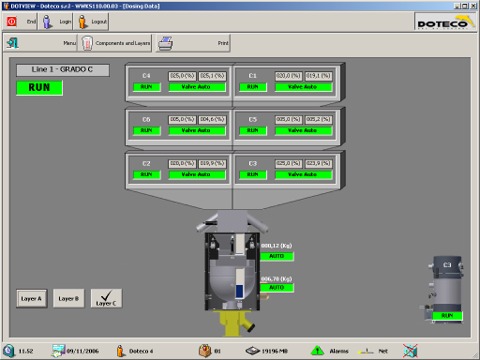

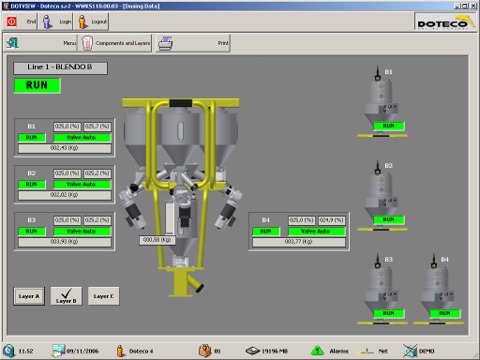

- A software package developed in MS Windows environment that provides a consistent process control and data management of the production plant.

- It is based on an integrated data acquisition system which can connect the DOTECO gravimetric units to a personal computer.

- The communication via Ethernet guarantees security, high communication speed and immunity against interference in heavy‐duty industrial environments.

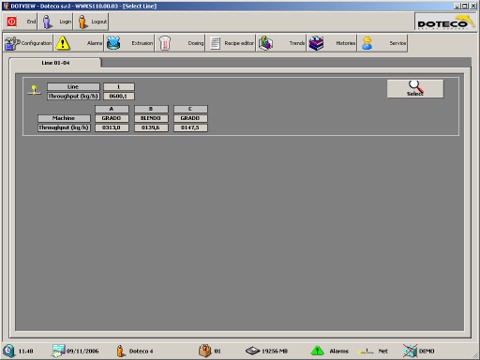

- Connection up to 20 extrusion lines

Dotexa Viewer – Data Control and Management system

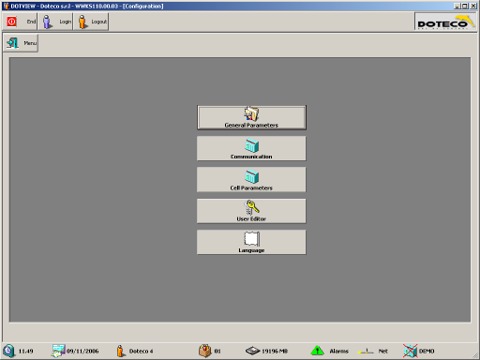

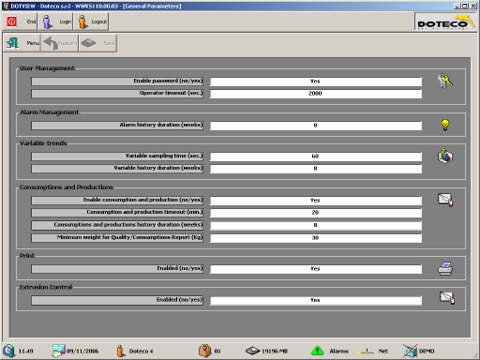

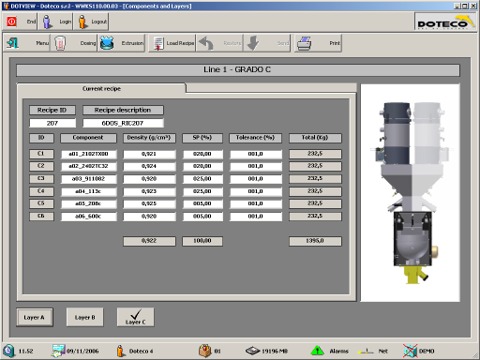

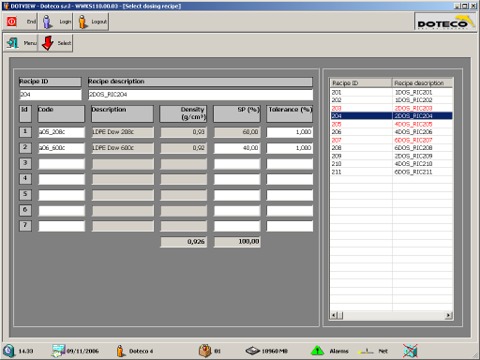

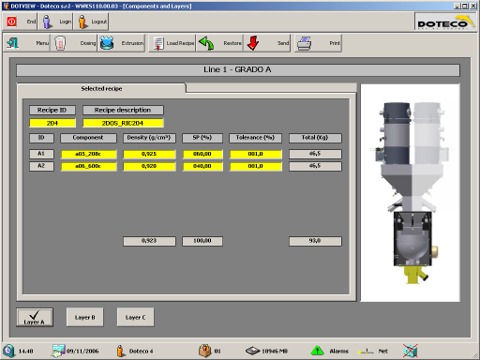

- Management of databases for process parameter storage. Recipes storing, upgrade and download on-the-fly.

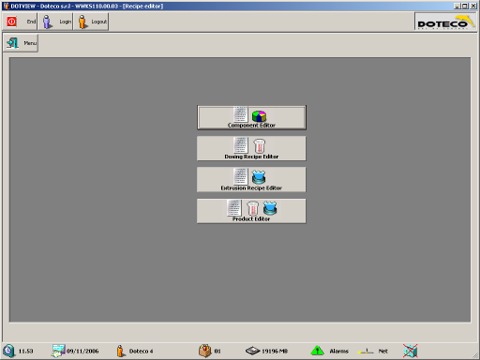

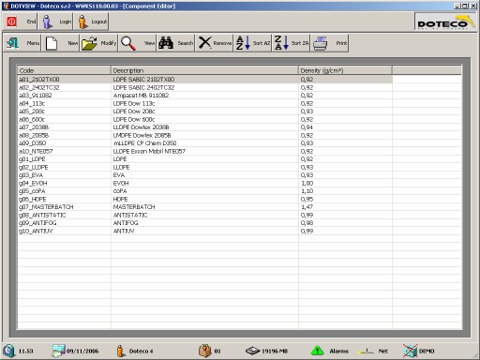

- Raw material manager: stored with numerical code and description.

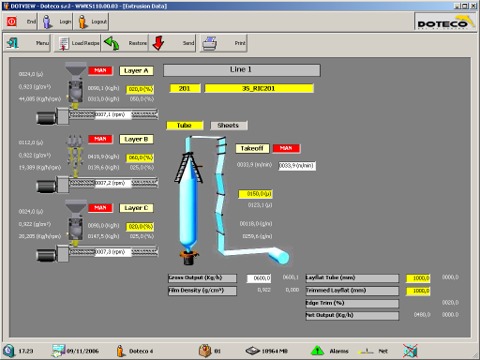

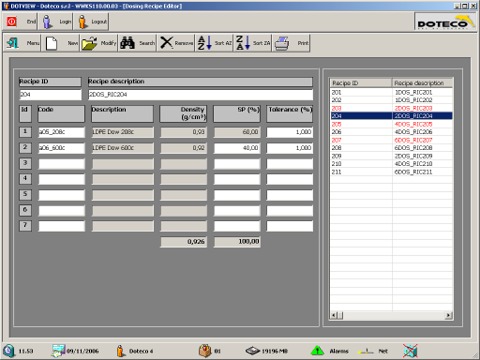

- Blending recipes manager: to create or modify and store blending recipes with numerical code and description.

- Melting profiles manager: to create or modify and store melting profiles with numerical code and description.

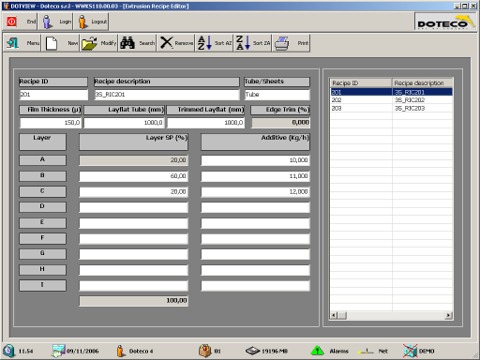

- Extrusion recipes manager: to create or modify and store extrusion recipes with numerical code and description.

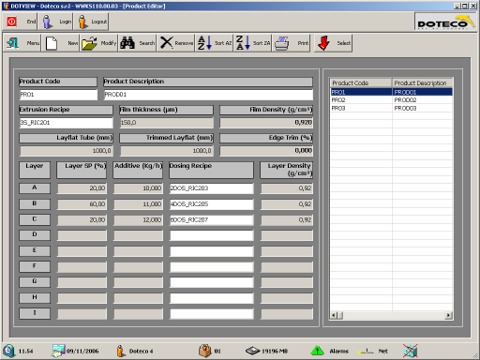

- End product manager: to create or modify coded end products. Each product code is assigned to a blending, extrusion and melting temperature recipes.

- Order manger: to create or modify a list of job orders containing useful data for identifying and tracking each order. Each order is assigned a product code.

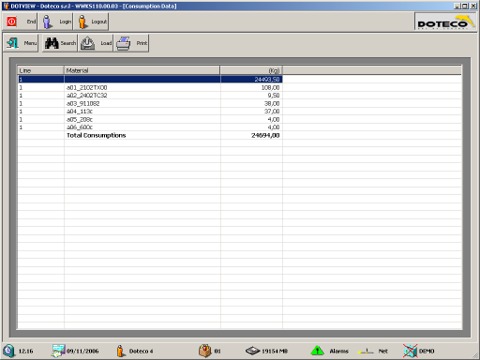

- Recording of the quantity of raw material used in the process.

- Totaling by ingredient.

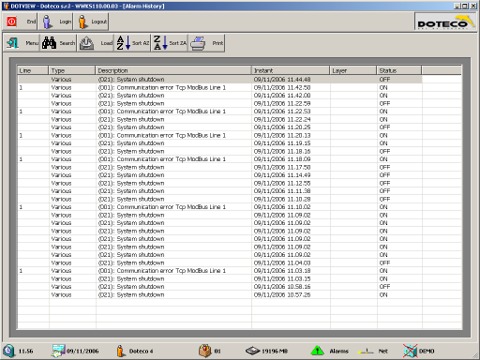

- Recording of alarm events.

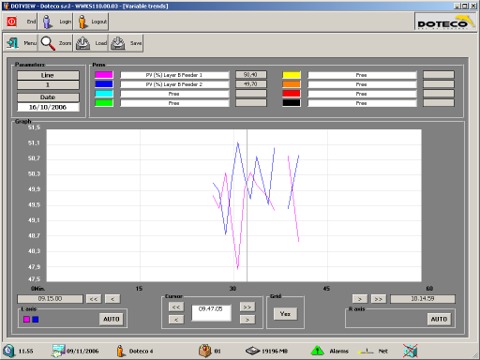

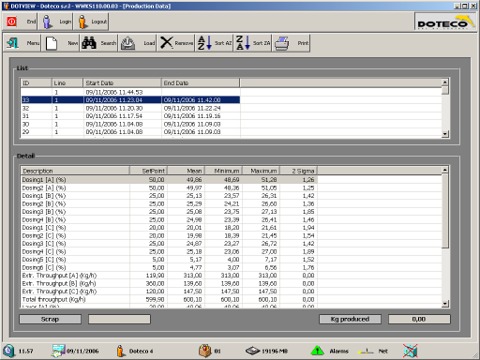

- Statistical process analysis (SPC) for blending and extrusion data.

- Data exporting for further analysis by user programs (Lotus, Excel).

- Inventory report viewing and printout: sorting by product code, job order, recipe and date.

- Quality report viewing and printout: sorting by job order.

Reporting

- Inventory report viewing and printing: sorting by product code, job order, recipe and date.

- Quality report viewing and printing: sorting by job order.