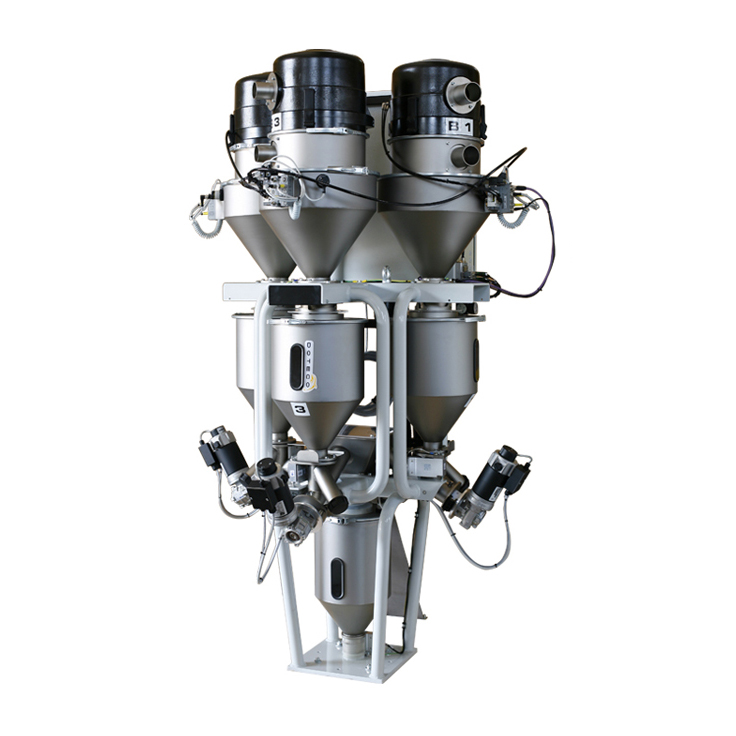

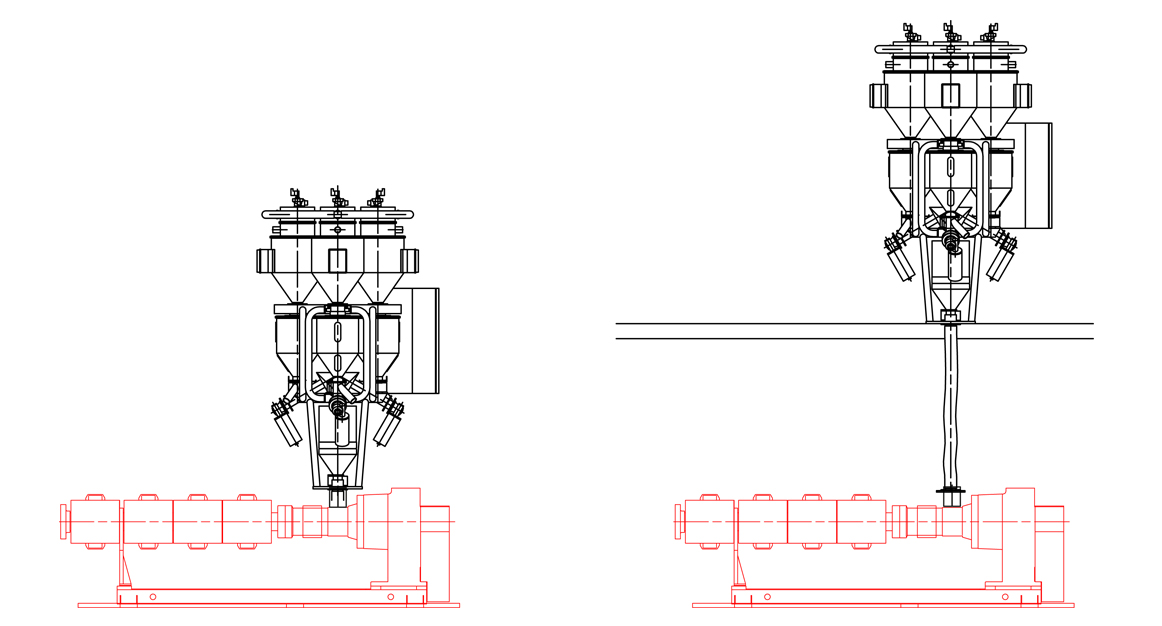

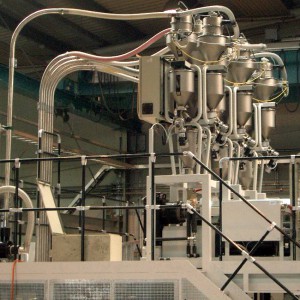

Continuous gravimetric blender, designed to blend pellets in extrusion processes where dosing accuracy and a homogeneous dispersion of additives are strictly required. Unaffected by vibrations, BLENDO has been designed to be easily mounted directly on the extruder throat to replace the conventional feed hopper or for mezzanine mounting

Blendo – Continuous gravimetric blender and extrusion control

- BLENDO is available in 16 models: 2, 3, 4, 6 or 8 ingredients, with throughputs of 150, 300, 600, 1000 up to 2000 kg/h.

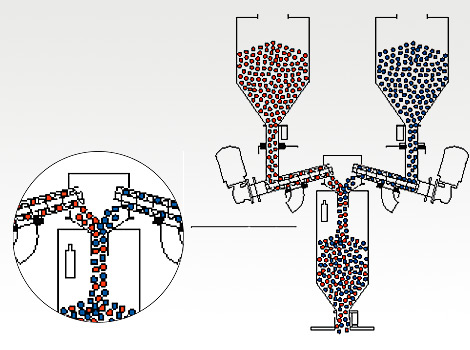

- Integral weigh downcomer hopper for extruder demand or gravimetric throughput control.

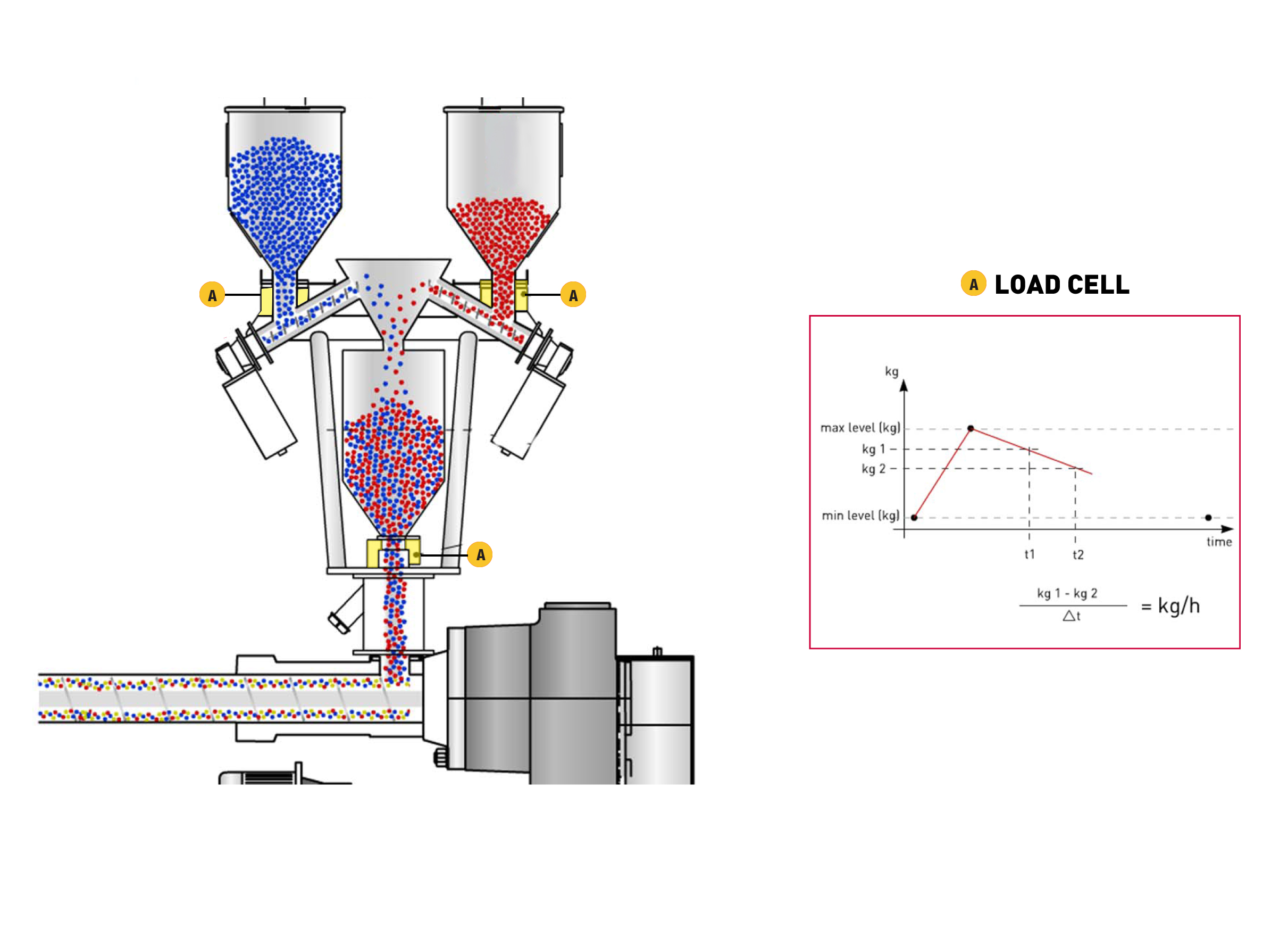

Load cell to sense variations in weight (no ultrasonic or capacitive sensor).

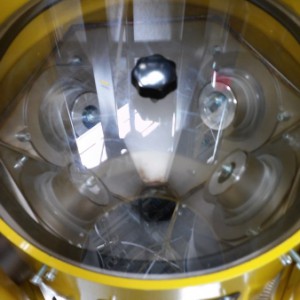

- A cascade mixer provides excellent additive dispersion, including ingredients with different bulk densities or granule size.

- Inclined screw feeders to improve metering accuracy and to prevent undesired dribble. They are driven, with a wide range of speeds, by DC motors with long-life brushes and closed-loop speed regulation.

- All parts that come into contact with the ingredients are made of satin stainless steel, or of food-grade materials or finishes.

- Easily accessible auger screws for quick and thorough cleaning, no tools required.

- Reduced installation costs. Complete wiring of the dosing unit is carried out by the manufacturer.

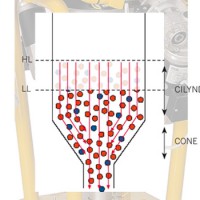

- Feed hoppers with sight glass for visual level control and quick-release ring clamp for easycover removal.

CONTINUOUS BLENDER OPERATION

- Precise continuous loss in weight control.

- Weight loss of each ingredient is measured.

- All ingredients are simultaneously metered through the auger directly into the integral weigh downcomer hopper, through the cascade mixer.

- The weight of blended material in the downcomer hopper is continuously monitored to sense level variations caused by changes in extruder throughput or non-alignment between the feeders and extruder throughputs.

- The feeders are individually controlled to achieve and maintain the preset blend ratios and to keep at the preset value the downcomer hopper level.

- This means that the blending throughput is always aligned with that of the processing machine.

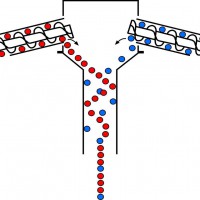

CASCADE MIXER ACTION

- The ingredients are simultaneously metered in the right proportion directly into the cascade mixer where the different streams are mixed to form a homogenous blend with a perfect dispersion of additives.

Integrated loading system control (SmartConvey)

Fully automated loading system control, easy operated by the same interface used for gravimetric blenders. One or more vacuum pumps to serve more than one receivers whose association can be set through configuration. All receivers linked to the same pump are served in turn, according to a priority sequence automatically assigned. Loading active control to reduce ingredient at minimum on changeover

High temperature

- High temperature version with special components (load cells, screw housing, lids and seals…) and protection covers.

Side component dosing

- Volumetric feeder for additives designed to be mounted on a neck riser, between the processing machine feed hopper and the extruder throat.

Materials suction lances

- Different designs to ensure optimal suctioning regardless of the material bulk density.

WIDE RANGE OF NETWORKING OPTIONS FOR REMOTE CONTROL AND DATA ACQUISITION

- OPC via Ethernet (one entry-point)

- OPC via CanBus (one entry-point or multi entry-point)

- ModBus TCP/IP (one entry-point)

- RS485/422 ModBus (one entry-point or multi entry-point)

- Profibus (one entry-point or multi entry-point)

- CanBus (one entry-point or multi entry-point)

- Profinet (one entry-point)

- Ethernet I/P (one entry point)