A NEW MEMBER OF THE ADROIT FAMILY!

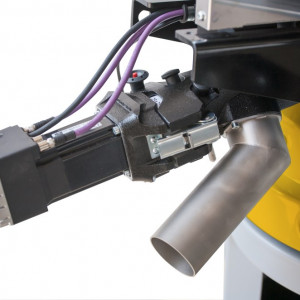

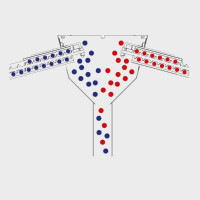

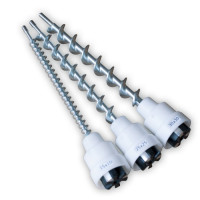

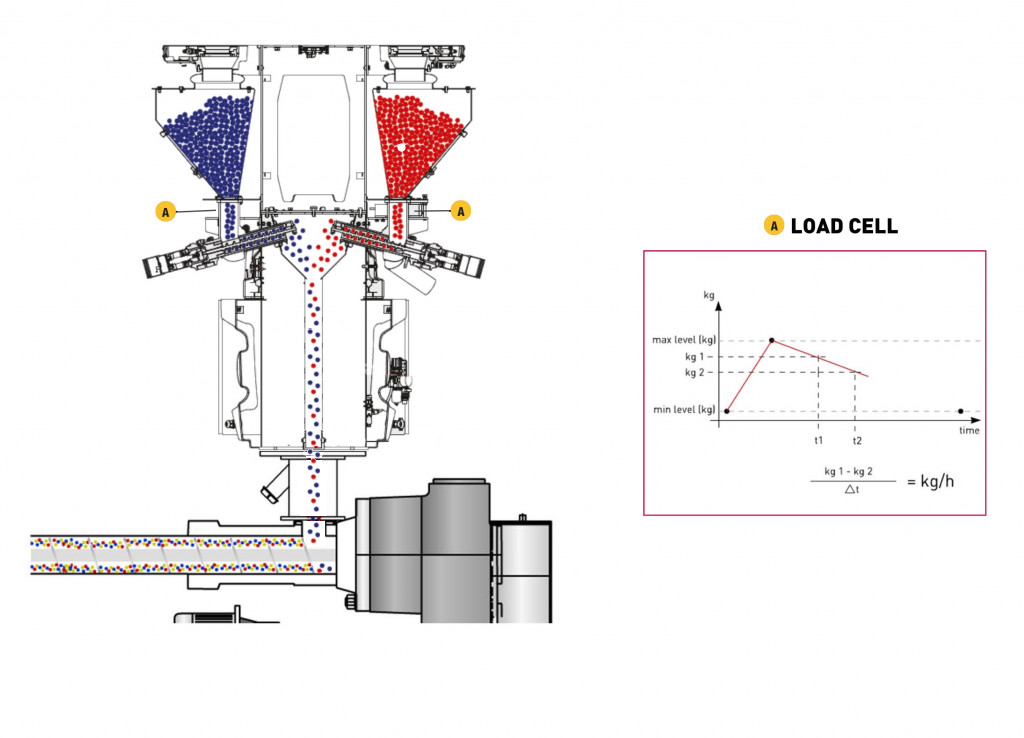

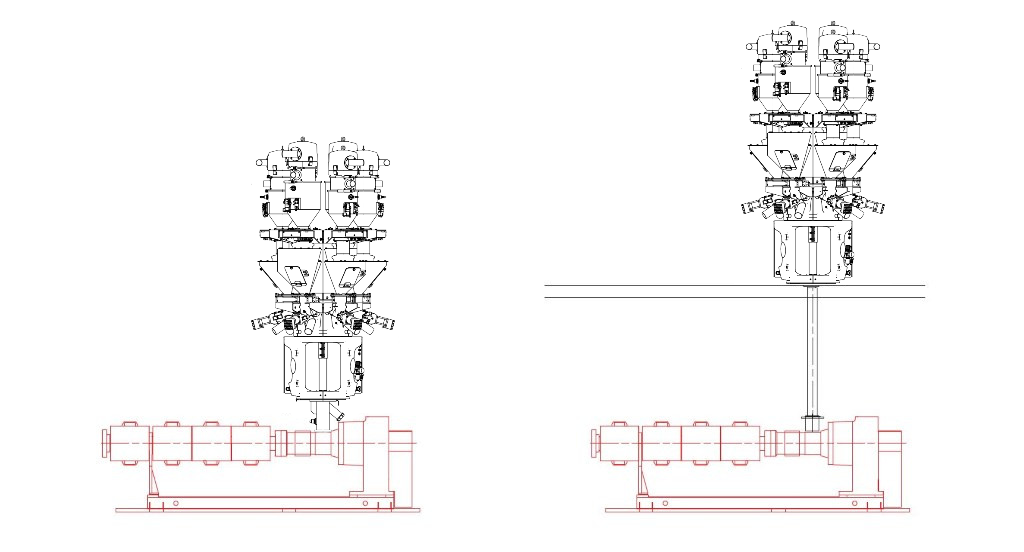

COMPO ADROIT AF is specifically designed to blend pellets in starve fed extrusion processes, where high dosing accuracy and a homogeneous dispersion of additives are strictly required. Available from 2 to 6 ingredients and with throughput up to 200, 400 and 800 kg/h. Its modular structure allows to increase the number of dosing stations even after the installation.