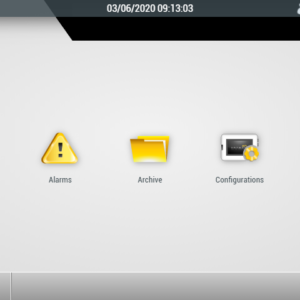

- Intuitive graphic interface.

- Wide range of settings, alarms and data reports.

- Integrated remote support via VPN service.

- Remote access from any device connected to the same network.

- Graphics automatically adapt to the screen, no matter the size.

- ALL in ONE solution: Doteco control softwares on the same device.

- Multi language.

WBOX

HARDWARE

HANDHELD AND PANEL MOUNT AVAILABLE

- Touch screen display

- Solid state drive; highly reliable, large capacity

- Full color display

- USB service port and Ethernet for remote connection

- Handheld device sizes: 7” and 10”

- Panel mounting sizes: 7″- 10″- 15” and 21”

SOFTWARE

- New architecture coded in HTML 5.0.

- Works with multiples process control software on the same device (i.e. blenders, IBC, air ring for gauge control).

- Integrated VPN system for remote technical assistance (standard on all models).

- By using the VPN it is possible to download updates for the CPU and Wbox.

- Computers within the same network can easily access to WBox.

- The same process can be monitored by different devices thanks to a password system.

- Multiple languages available, including CJK characters (CN, JP, KR).

- Very intuitive visualization through colored alarms and icons.

- Select who can access and grant different level of permissions, with a customizable users management fuction.

- Thanks to the solid state hard disk, no additional storage needed.

- Combined with the latest X-20 CPU, computation time is much shorter.

- Minimized downtimes with the remote technical support.

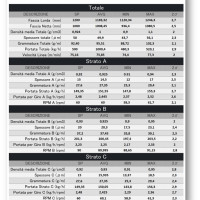

- Complete and detailed reporting system, to maximize output quality and material wasting.

- Handheld device comes with 15 mt cable to ensure full mobility.

- Control all the processes from your desk, remote access available within the same network.

- Concentrate only on what matters, all Doteco process softwares installed on WBox share the same architecture, minimizing the learning process.

PARAMETRIZATION

Parametrization

- Set the optimal parameters of the Adroit series blenders.

Users management

- Three different users types, with different privileges (from visualization mode only, to Doteco technical service level).

Help section

- A visual explanation of all the setting icons.

Remote Assistance

Doteco’s service team will be able to support the users by:

- Checking the blenders status and its parameters.

- Uploading PLC software updates on the WBox (once the procedure is completed, the update can be downloaded on a USB drive and transferred to the PLC).

- Updating the WBox.

- Using the WBox to directly connect to the PLC.

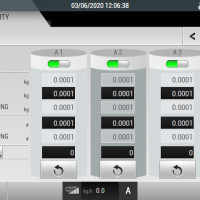

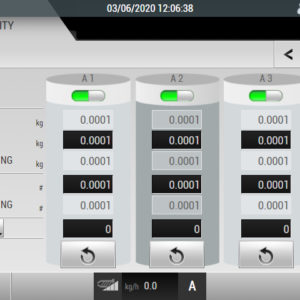

DOSING

Dosing application includes all the Parametrization functions plus:

- Set the dosing percentage of each component.

- Check/Set the loading system (if implemented).

- Check/Reset the consumption’s totalizers set values for each component.

- Visualize, for each component loaded in the hoppers, density and totalizers.

- Check/Set the dosing slide gates status (auto/open/closed).

- Check/Set the batch slide gate status (auto/open/closed).

- Check/set the mixer scoop status (auto/on/off).

- Upload/Save a recipe.

- Load and set a recipe.

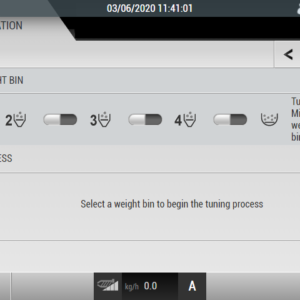

SPC mode:

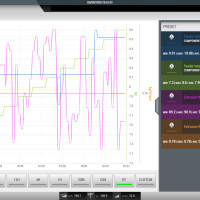

In the SPC settings page, the user can set the sampling options in order to obtain relevant performance statistics.

EXTRUSION

Extrusion control application includes all the Dosing functions plus:

Extrusion and haul off speed control:

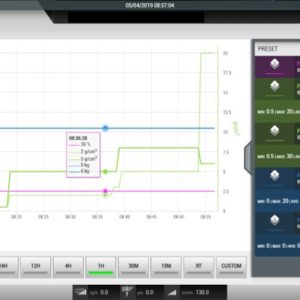

Visualize and set values of: throughput, thickness, weight, density, layflat, layers percentage, layers throughput and haul off speed (if enabled). Furthermore are displayed the real values of: layers production, layers thickness, screw models and speed.

SPC mode:

In the SPC settings page, the user can set the sampling options in order to obtain relevant performance statistics regarding the extrusion process control.

OPTIONALS

- Intelligent Loading System (CAC), to minimize residual material in the hoppers and speed up cleaning procedures.

- Advanced Reports, to record performances over the time.

- Variable Trend Statistics, to monitor variables for quality control purpose.