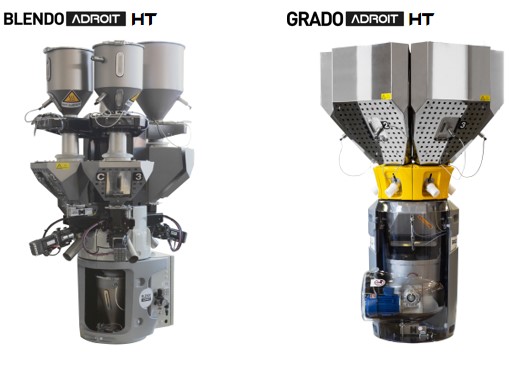

23 Nov ACCESORIES: ADROIT HIGH TEMPERATURE VERSION

Discover Doteco’s solution for high temperature materials dosing, the ADROIT HT version.

AN “HOT” TOPIC

Due to the hygroscopic nature of some polymers, such as PET, maintaining the lowest humidity level possible it is fundamental to preserve their characteristics. Humidity is usually kept low by heating the materials at temperatures up to 180°C (356°F). The extreme heat conditions the blender is exposed to, could alter the chemical characteristics and structural integrity of some of its components, limiting the normal functioning or even break it.

For the above mentioned reason, Doteco developed an ADROIT blenders version specifically designed for handling high temperature materials, without limiting the performances and the operator’s safety.

SAFETY FIRST

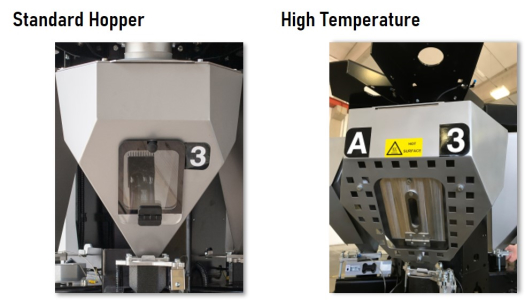

Ensuring personnel safety is imperative. ADROIT HT blenders hoppers are equipped with a protective shield, to avoid that the operator unintentionally gets in contact with its hot surfaces. Safety, without limiting operativity! On each aluminum made inspection hatch, it’s embedded a tempered glass window to allow the user to monitor the material level within the hoppers anytime.

PERFORMANCE GUARANTEED

Capacitive sensors that can operate at high temperatures and special load sensing cells, ensure fast reactivity of ADROIT HT blenders, even under severe heat conditions.

Accuracy and precision are critical indicators of a good performance over time. For this reason it is very important that, despite the adverse conditions the blender is capable of dispense materials in the most accurate and precise way possible. Dosing units and slide gates are made of heat wearing resistant materials, for the stability and repeatability of the dosing process over time.

If that’s not enough, for the customers that require an exceptional output quality: BLENDO ADROIT HT version is equipped with airtight seals, to completely prevent external air humidity to alter the dryness level of the materials.

RELIABILITY

Heat can sensibly increase components wearing, consequently leading to frequent downtimes caused by unplanned maintenance.

To avoid expensive downtimes, crucial components such as cylinders, air hoses and mixer motors, are made of materials that can withstand heat.

Where it is not possible to utilize heat resistant materials, components are protected from high temperatures by dissipators.

The contents on the website www.doteco.com of which Doteco S.p.A. is the author they cannot be copied because they belong to the author himself. Copying and reproduction of the contents in any way or form is prohibited. The sharing and redistribution of content is permitted as long as the source is cited and the link to the page from which they were taken is reported. Copyright © 2020 Doteco S.p.A. All rights reserved