17 May Loading system BLENDO – principle of functioning

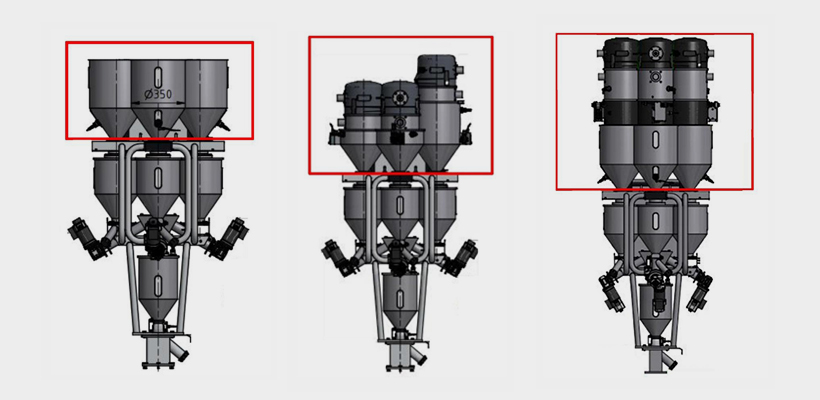

There are three possible configurations:

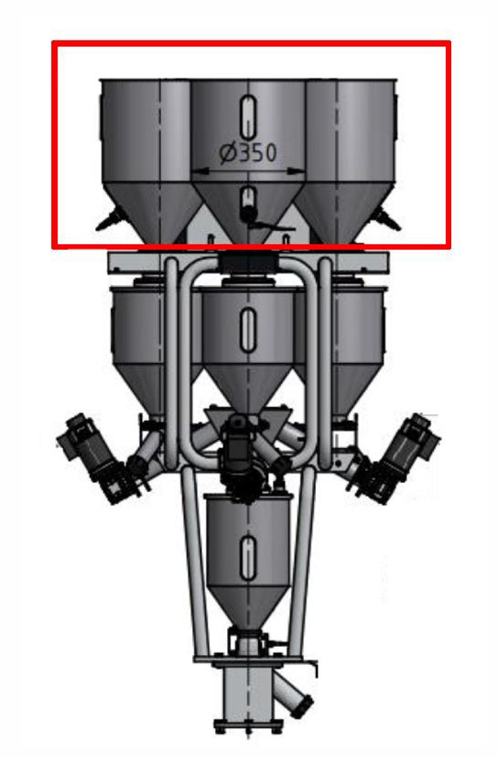

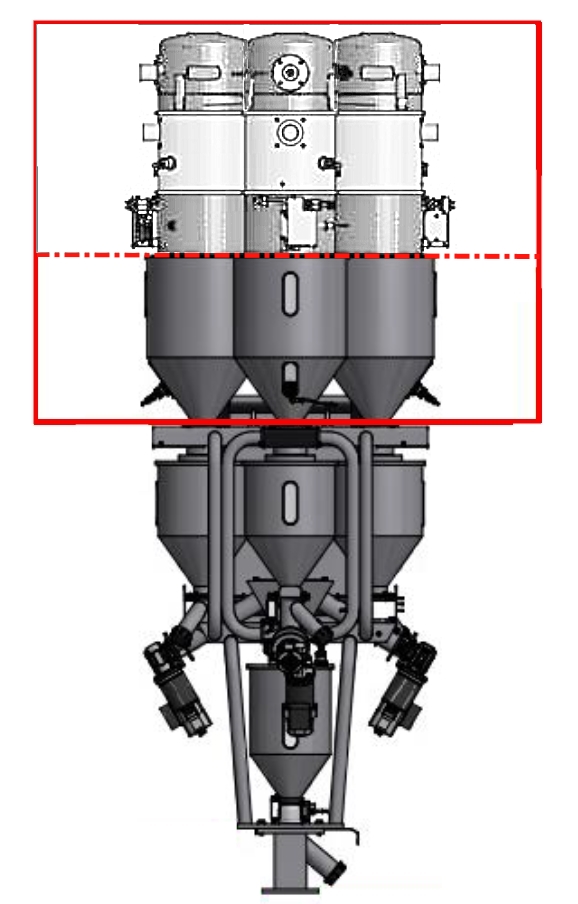

BLENDO with pre-storage hoppers.

This configuration is supplied when the loading system is not present or is not supplied by DOTECO. The customer can add their own receivers with flaps or the operator can load manually the components in the pre-storage hoppers (suggested only in case of low throughput of the dosing station). The pre-storage hoppers are supplied with a level sensor, handled by the BLENDO‘s PLC, with the aim to inform the operator when the level of the material is VERY LOW. The sensor, in normal working conditions must be covered and the operator needs to ensure that in the hopper there is always enough material to fill completely the gravimetric hopper, without discover the sensor. For that reason, the volume of the pre-storage hopper must be always higher than the volume of the gravimetric hopper.

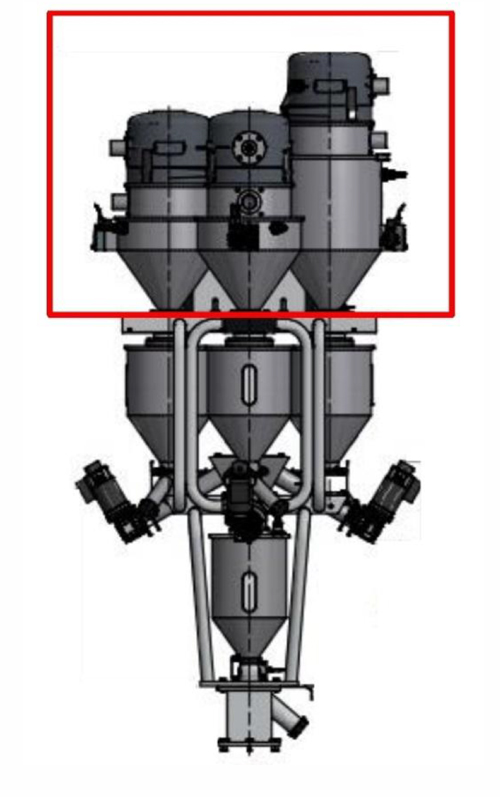

BLENDO with Vacuum Head Receivers.

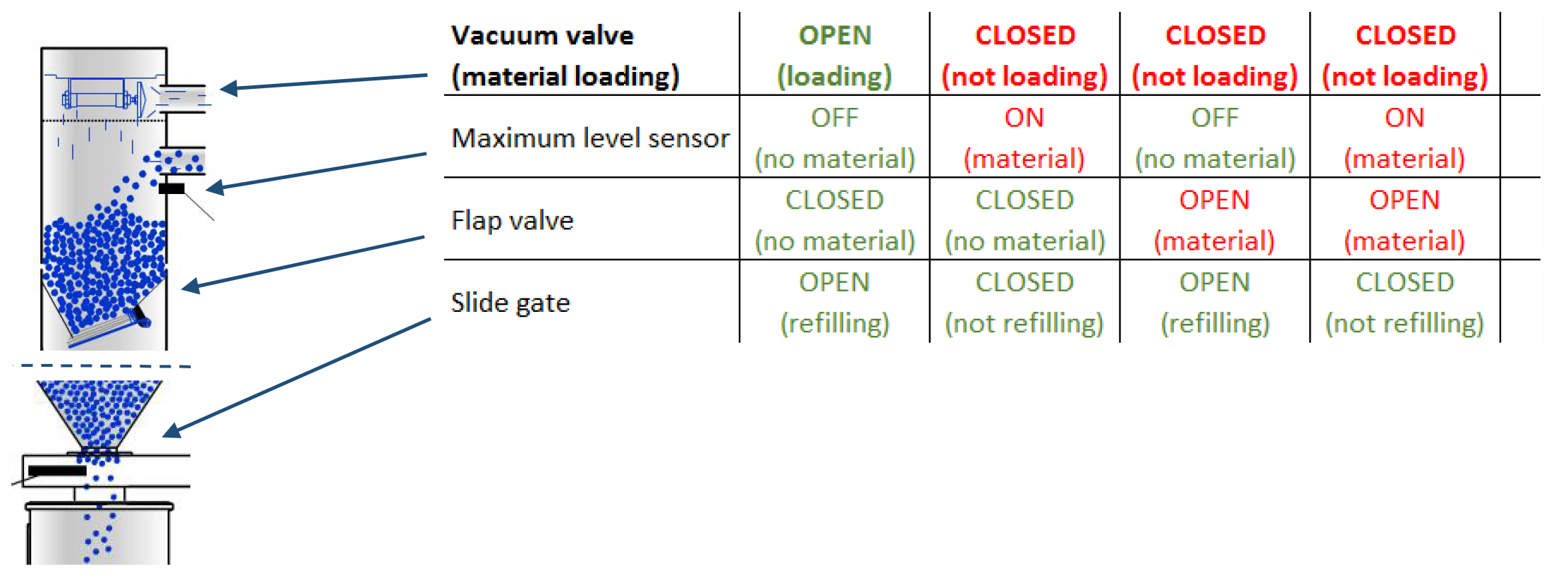

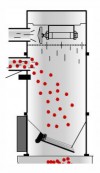

This configuration is the more compact and efficient, provided by DOTECO as standard when we supply the integrated loading system SMART CONVEY. The pre-storage hopper integrates a suction head with a valve that open and close to enable \ disable the vacuum:

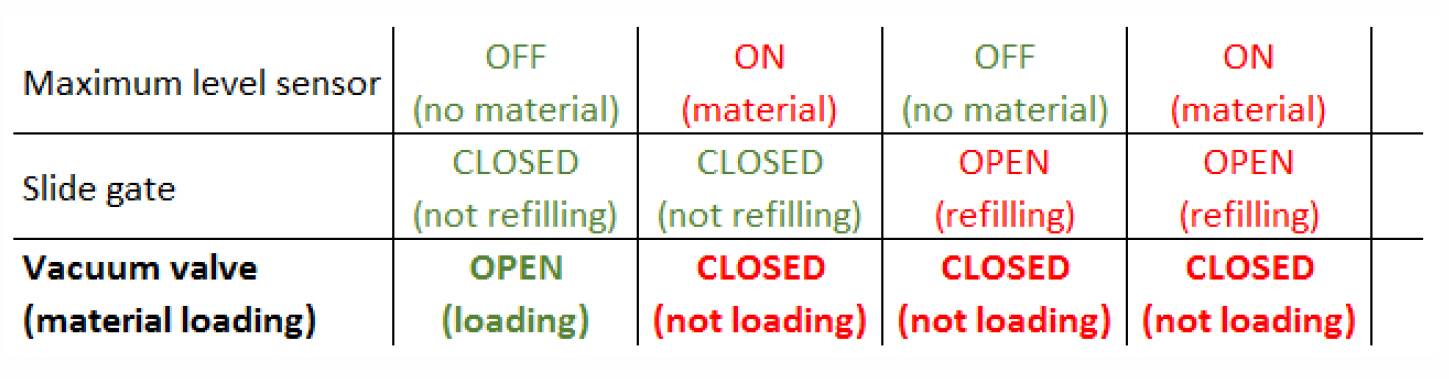

The valve opens only when the maximum level sensor does not read presence of material and the slide gate for refilling the gravimetric hopper is closed:

The loader cannot function if the sensor reads (means the receiver is full of material) and if the slide gate is open (the negative pressure drops down).

It is also possible to install vacuum heads by a third party but in that case who controls the vacuum pad must consider the status of slide gate and sensor (see table above). DOTECO can provide the two signals as “dry contact” through a relay, or a single contact connecting the two signals in series (option).

BLENDO with vacuum receivers with flap valve

In this case the loading receivers are independent by the machine status (slide gate open for refilling or not) and it is not necessary any level sensor on the pre-storage hopper. It is ideal when a third party provides the loading system and there are no signal exchanged with the blender.

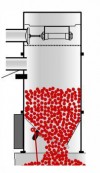

The loaders is an independent unit that works with a flap valve:

Flap valve open

Material present

(not loading)

Flap valve closed

Material low level

(loading)

When the flap valve is open it means that there is enough material in the pre-storage hopper. A dedicated sensor detect if the flap is closed and, only in this case, the loading cycle can start. Since the flap valve is sealing the receiver, the status of the slide gate is not important. What determines the start of the loading is only the sensor of maximum level: