29 May Accuracy & Precision: 2° PART

In this second and final part, we would like to introduce the concept of Accuracy, how to “read” these attributes and some final considerations about DOTECO products.

II° PART: ACCURACY

Where are you aiming?

Despite the first experience with archery has been a bit disappointing, you decided to not give up and kept training hard to improve your precision.

Finally, today you will have the opportunity to test your skills in your first official contest. Good luck!

At the end of the session, here’s how the target looks like:

On one hand, all the arrows ended almost in the same spot, however none of them hit the center of the target.

So, how is your performance going to be rated?

Well, all the arrows has been shot with high precision but…. with very low accuracy!

So what does accuracy mean then? Accuracy is, on average, how far is the real output, or result of a process (in this case the arrows shot) from a pre-set value (you were expected to hit the center of the target); even if you managed to send all the arrows close to each other (high precision), all of them landed way off the desired area (low accuracy).

Accuracy and Blenders

As we mentioned in this article about precision, there are many similarities between archery and dosing processes. A good performance doesn’t only involves that the arrows lands as closer as possible one to each other, but mainly it is required that they hit the center of the target.

In the same way, a good blender must be able to dose always the same amount over time (high precision) and in the expected quantity (high accuracy).

Let’s see an example:

In order to be able to monitor the accuracy, first it is necessary to set the recipe and choose a desired throughput (kg/h), then at constant intervals of time we take samples of one of the ingredients and weight them.

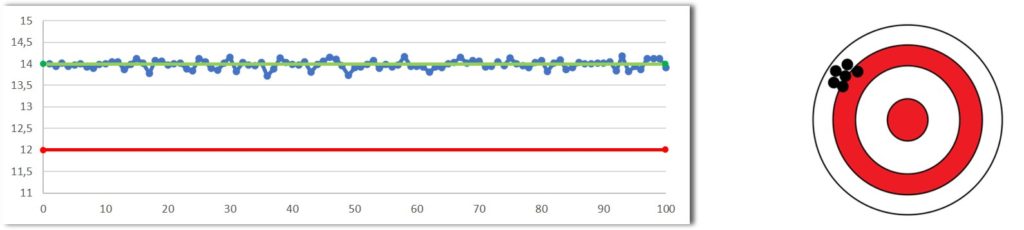

Once we have a sufficient amount of samples, let’s visualize them by displaying in a chart as shown below: the blue dots represent the single measurements (samples), the red line indicates the pre-set value and the green one the average of the observations.

It is immediately noticeable that, despite the fact that the material quantity in all samples is very close to the average (good precision), the whole data collected is shifted from the set-point (low accuracy). Same as in the archery example next to the chart, the arrows landed close one to each others, but very far from the center of the target.

In other words, the blender is dispensing the ingredients always in the same amounts and proportions, but not the ones we wanted!

Let’s try again, but this time we will use an high end blender.

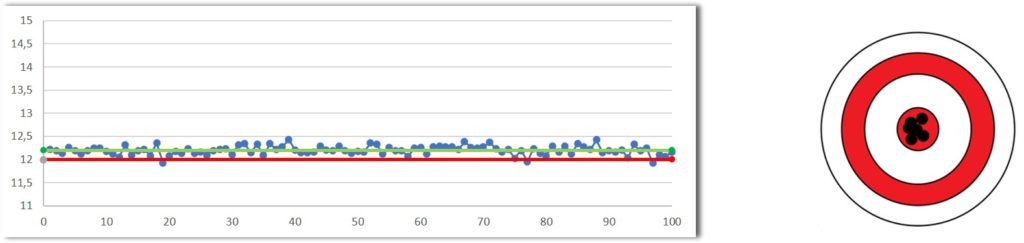

Compared to the first test, the samples average (green line) are now very close to the pre-set value (red line)*.

Now the blender is dosing the expected amount and percentage of ingredients (high accuracy).

*the distance between the red and green line has been exaggerated for visualization purposes.

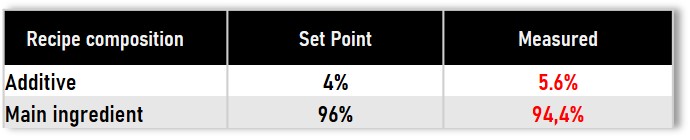

Here is another simple numeric example to show the effects of accuracy on the ingredients percentage.

On the first column are listed the recipe ingredients, on the second one the set point percentage – in other words the desired proportions of each ingredient – and in the third one, highlighted in red the actual measured percentage of each component. The higher will be the discrepancy between the actual measured values and the pre-set ones the lower will be the accuracy, the higher will be the cost of dosing not necessary additives.

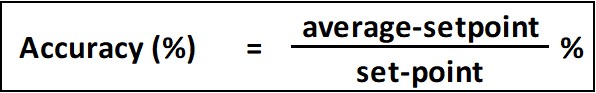

How to calculate accuracy

Is there a way to measure accuracy?

Yes! Accuracy, is given by the ratio between the average set-point (the measurements average) and the set-point (the desired output).

The lower the value will be, the higher the accuracy.

Low accuracy, high costs

Accuracy might have a relevant impact on the process final outcome.

A low positive accuracy, results into an excess of material dispensed, which will translates in an higher and not needed extra material consumption.

On the other hand, a low negative accuracy means that the ingredients will not be dosed as required and the final product will not meet the specifications.

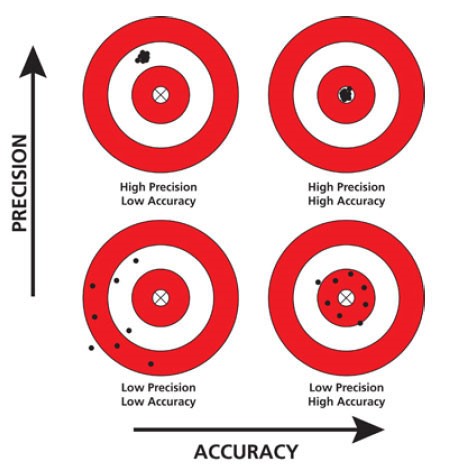

Accuracy and Precision

The picture below combines precision ad accuracy at different levels. The horizontal axis represent the accuracy level from low to high, while the vertical one depicts different degrees of precision.

All that glitters is not gold

Now that we have a better idea of what precision and accuracy mean in dosing processes, how can we correctly interpret this data when it is provided to us, for example by a manufacturer?

There are some conditions to be taken in consideration to be able to correctly judge blenders quality performances.

Technological and natural limits: errors are unavoidable, surely technological advancements allowed us to reach very high standards, however there are constraints related to the very nature of things so that even if infinitesimally small, there will always be a certain degree of error. Just think of limits such as the resolution of the load cells, vibrations, errors on tolerances.

Numbers should be contextualized: sure it is of great impact to display low percentages on a brochure, but without a context, in reality, there’s little to no meaning. Precision and accuracy vary, depending on various factors such as the material type, environmental conditions and throughput rate.

For example, the smaller the throughput rate the higher will be the impact of a variation in the dosed quantity with respect to the set-point.

Class of accuracy: while reading specifications sheets, be careful to not confuse blenders accuracy and precision level with the so called “load cells class of accuracy” (the error tolerance of the load sensors). In reality accuracy and precision are the result of many different factors which includes load cells class of accuracy but not only: for example how it is mechanically engineered, the quality of the electronic components and the software architecture.

Homogeneity: There is a 3rd key factor that greatly influence the output quality, the ability of the blender to mix all the ingredients homogeneously. A well designed mixer, can contribute to lower the incidence of dosing errors, consequently helping to increase the overall blender performances.

DOTECO

With the ADROIT series, Doteco has reached new heights in dosing performances.

The software: the core of the blender, now includes specific and complex predictive algorithms to reduce fluctuations and increase the output consistency.

GRADO ADROIT is equipped with:

- Load sensing cells with high resolution electronics (24 bit – 0,004 gr), installed on vibrations and shocks absorbers.

- Low inertia techno-polymer slide gates, allowing the open/close transition much quicker compared to other systems.

- Specifically designed mixer to grant homogeneous batch blending and to avoid material stratification.

- Load sensing cell with high resolution electronics (24 bit – 0,004 gr).

- High performance dosing screws: low tolerances, reduced friction, inclined to avoid accidental material drops.

- Cascade Mixer: special design and gravity, jointly provide an incomparable homogeneity.

The contents on the website www.doteco.com of which Doteco S.p.A. is the author they cannot be copied because they belong to the author himself. Copying and reproduction of the contents in any way or form is prohibited. The sharing and redistribution of content is permitted as long as the source is cited and the link to the page from which they were taken is reported. Copyright © 2020 Doteco S.p.A. All rights reserved